In 3D printing, a special printer creates three-dimensional physical objects via an additive manufacturing process. 3D printing has been around in some form for decades, but only in recent years has the technology become so prevalent and so available that anyone with a few hundred dollars to spare can own a 3D printer at home. 3D-printed products are often customizable, use less material, and produce less waste—they are also typically lighter-weight than traditionally manufactured products, making them easier to ship.

The global market for 3D printing products and services was projected to hit nearly $25 billion in 2024, with an expected value of over $37 billion by 2026. Want to get in on this growing industry, but aren’t sure where to start? Here are some 3D printer business ideas to get the ball rolling.

1. Models & Miniatures

Classic tabletop games—think Dungeons & Dragons or Warhammer 40k—have always had a strong niche community of enthusiasts. People often play these games by moving small models or miniatures around a physical arena.

The interest in models is distinctive enough that the collection and customization of miniatures (by painting them, for example) has become a hobby in its own right, so demand for these miniatures remains high within these gaming communities. 3D printing is a perfect way to create the small but highly detailed models that characterize these tabletop games.

(Source: RareCandyCreationsUK on Etsy)

Your first step: Check online forums, boards, and community spaces to gauge how strong demand in your area is for gaming-related models and miniatures. Note the average prices and model sizes.

Being a dungeon master for a Dungeons & Dragons game is one crazy (but effective) way to make some money on the side, or even turn into a full-time business. Our list of crazy business ideas for entrepreneurs lists many more ideas.

2. Fashion & Eyewear

If tailored clothing and custom-fit eyeglasses and contact lenses are possible, why not take things a step further and use 3D printing to create truly bespoke fashion and eyewear pieces? Entrepreneurs can use additive manufacturing to create clothes and accessories from scratch, resulting in pieces that can be completely customized to a buyer’s body type or aesthetic preferences.

Not only does this result in items that are tailor-made to specific customers, but this business model also means that you won’t need to produce and store large quantities of product—which saves on inventory management headaches and expenses.

Your first step: Use free or paid resources to learn how to use a 3D printer to create clothing pieces and eyewear. Make sure you know how to adjust every part of the final product so that you can customize each piece to the exact specifications that buyers will need.

How much does a 3D printer cost?

A 3D printer bought online will cost you around $170–$2,000 (not including shipping). Food printers cost a bit more, from $999–$5,500.

Prices will vary depending on factors such as the exact additive manufacturing process the printer uses, what material is used to construct the final products, how large the products can be, the printer’s available toolheads, printing speed, and whether the device can print in color.

3. Rapid Prototyping for Entrepreneurs

Entrepreneurs who create their own products—especially complicated, novel, or unusual products—often follow the principle of the minimum viable product. This refers to a preliminary version of the product with just enough functionality to elicit feedback from users. The developers then use this feedback to make adjustments and improvements for the next (but still preliminary) version of the product, which will again be sent to users for testing and feedback. This entire process is called rapid prototyping.

Entrepreneurs’ need for rapid prototyping is an opportunity for owners of 3D printers to rent out their machines for this purpose. Because rapid prototyping inherently requires many iterations of a product prototype, entrepreneurs and printer owners can develop long-term business partnerships.

Your first step: Connect with entrepreneurs and new business owners in your area, and let them know that you are interested in helping them create any prototypes or test products they need.

How much does it cost to rent a 3D printer?

Rental costs vary, and can depend on the duration, such as daily or weekly. For a one-week rental, expect to pay between $120–$200+. If you’d like to rent a printer for a month, prepare $650–$2,000.

4. Education

3D printing also has applications in the education sector—creating scientific or laboratory equipment, tools and anatomical models for medical and dental school, architectural models, manufacturing simulations, and various teaching aids. Students in business school could also use 3D printing technology to actually create test products and perform rapid prototyping as part of a test or practical exam.

While some educational institutions may prefer to buy their own 3D printers, an entrepreneur who can secure a few of their own printers may be able to rent these out to universities or study groups.

Your first step: Talk to faculty members (or students) in local academic institutions to see if anyone there could benefit from the services of a 3D printer. Students of medicine and dentistry, architecture, business, and engineering are all good bets.

5. Jewelry

3D-printed jewelry is a creative, flexible, and potentially lucrative option as a business. Come up with a jewelry concept, and then flesh it out via computer-aided design (CAD). You can also choose to take existing designs and tweak or add your own personal touches to them (just be sure to credit the original design owners).

Depending on your preferences or the materials available, your 3D-printed jewelry can have different finishes or be made out of different things. Check out what people want or are looking for online, or print whatever you want and see who’s eager to buy it.

Your first step: Come up with a jewelry concept or set of designs you’d like to print; and put these into CAD software. Or do some research and see what kinds of jewelry pieces people would like to have made.

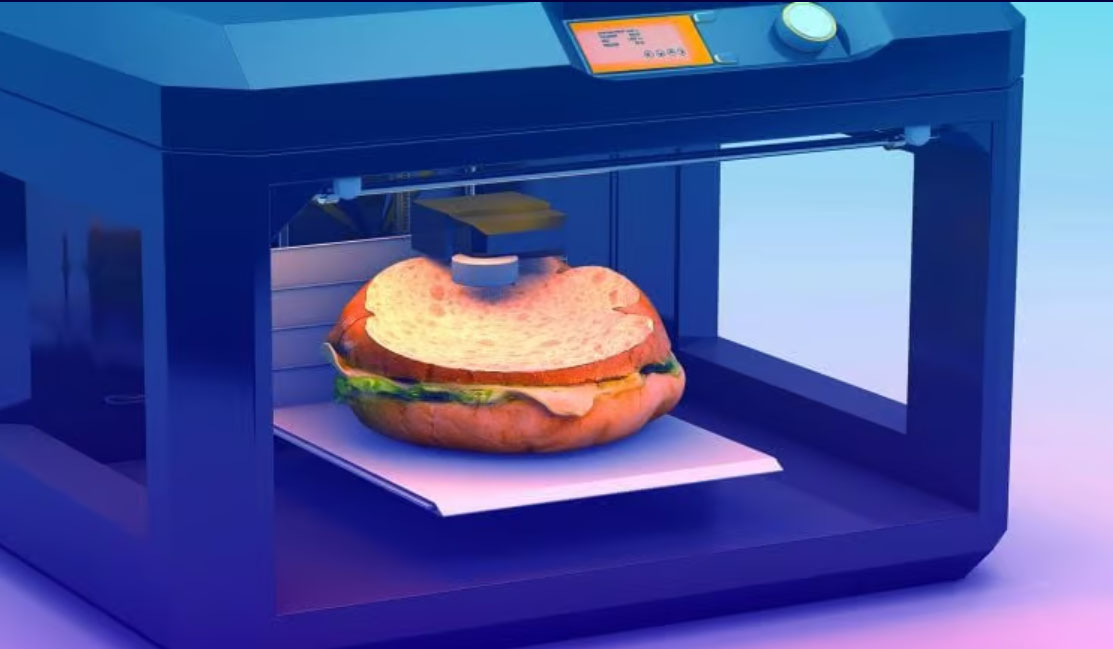

6. Food Printing

As 3D printing essentially involves adding material layer by layer until you complete a final product, the process lends itself very well to creating decorative food items. Intricate pastries, multi-tiered cakes, and food items designed to look like other objects are all possibilities.

Besides the aesthetic side of food production, the precise control possible with 3D printing means that food manufacturers can add or manipulate exact quantities and specific ingredients. This is not only invaluable for procedures with precise requirements (such as baking), but also useful for customers with special dietary needs.

(Source: Shutterstock / Built In)

Your first step: Decide what types of food you will be printing. Search online for recipes and instructions that you can feed into the printer to come up with the exact result you want. Most 3D-printed foods must be converted to a paste or gel before being loaded into a canister for printing. And you’ll want to obtain the appropriate health department licenses before selling your 3D-printed food to the public.

While you can start simple with 3D printing food, the technology’s high level of customizability also makes it an attractive business option for big names like NASA, which is looking to create custom-made high-nutrient foods for its astronauts. Other tech and health-based startups are also getting in on the action.

7. Household Accessories & Decor

Items produced by 3D printing don’t necessarily have to be functional or useful; they can also just be interesting to look at. Printers can be used to make creative and unique household accessories and decor: vases and planters, small sculptures, clocks, picture frames, bowls and other kitchen items, bedside lamps, custom shelves, modular boxes, and more.

These accessories and decor will likely be relatively simple to manufacture and sell, compared to more complex things like medical equipment. You can also choose to mass-produce accessory items of your own design, or create custom pieces that customers request.

(Source: Merilumies on Etsy)

Your first step: Check out the current best-selling home accessories and decor online. Take note of the existing designs, as well as any feedback, requests, or wishes that viewers leave on the product pages. Use these as inspiration for your own designs and products. Or, connect with customers yourself and accept custom requests.

Bottom Line

Now that 3D printers are so widely available and affordable, it would be a waste not to explore the business opportunities that come with this technology. As with any other business venture, begin by evaluating the level of demand, taking stock of your resources and checking what equipment you can afford, assessing costs, and setting pricing. Then, focus on creating and delivering great products for your customers.