Inventory management is the process of having the right products, in the right quantities, at the right time to sell to customers. Accurately managing inventory can increase revenue by preventing stockouts, excess inventory, and unsold products.

While I have seen it done manually, the easier and more reliable solution for managing inventory is to use a software program that automates your inventory management processes. Our recommended solution for inventory management for small businesses is Lightspeed, as it combines both the POS system and inventory management suite to streamline your operations.

If you’d rather manage inventory manually, download our free inventory management workbook:

Thank you for downloading!

Lightspeed offers the best inventory management system for small businesses.

Step 1: Choose an Inventory Management Method

Before you begin working with your stock, you need to choose an inventory management method. As I mentioned earlier, the methods you choose should be ones that best allow you to maintain the right products, in the right quantities, at the right time to sell to your customers.

In my experience, combining a few different inventory management methods is the best way to successfully manage inventory.

The inventory management method (or methods) that makes sense for your business will depend on a few factors, including:

- Product quantity

- Product value

- Cost of goods sold (COGS)

- Turnover ratio

- Product type (perishable vs non-perishable)

- Product size/weight

- Product quantities

- Product variations

- Turnover rate

- Carrying costs

Once you have chosen your inventory management methods, you can implement them by programming an ordering cadence, automations, and alerts on your inventory management software or point-of-sale (POS) system. Or, if you are managing your inventory manually, you will need to monitor your books and item quantities to ensure implementation.

Below, you can click through a few of my most recommended inventory management methods.

First-in, first-out inventory management, also known as FIFO, is one method to assign costs to ending inventory. FIFO assumes that the first items that are purchased will be sold first to assign a cost to the inventory remaining at the end of the year.

The last-in, first-out inventory method, or LIFO, assumes the most recently purchased inventory (“last in”) as the cost of goods sold (COGS). In other words, recently purchased goods are expected to be expensed first or transferred to the COGS.

This method is popular in the US because it’s allowed for tax purposes, and many proponents believe it most closely matches the replacement cost of inventory.

The average cost method, or AVCO, is another method used to determine the cost of inventory at the end of the year and the COGS during the year. Under AVCO, the cost of inventory is based on the weighted average cost of inventory purchases during the year. Because it uses an average cost of goods in inventory rather than tracking individual units, it is typically simpler to use than FIFO or LIFO.

A perpetual inventory system calculates your COGS after each sale, as opposed to periodically. This is also called live sales tracking in a POS system and simply means that your inventory information will update as transactions happen. You will also want to be sure that this includes all your sales channels, including online and additional locations.

A periodic inventory system calculates your COGS periodically when you perform physical inventory counts. This is a more common practice for businesses managing their inventory manually but is also used less frequently in conjunction with automated perpetual inventory management systems.

The specific identification inventory method identifies each individual unit of inventory and assigns its actual cost. This inventory management method doesn’t use assumptions like the FIFO, LIFO, or AVCO methods. The COGS and ending inventory are determined by the actual cost assigned to each physical unit of inventory and what is actually sold and unsold.

Step 2: Organize Product & Vendor Information

The first step in organizing your inventory is to set up your stock and supplier information in a reliable and accessible system. Some businesses will use manual tracking methods such as spreadsheets to keep track of their products and vendors.

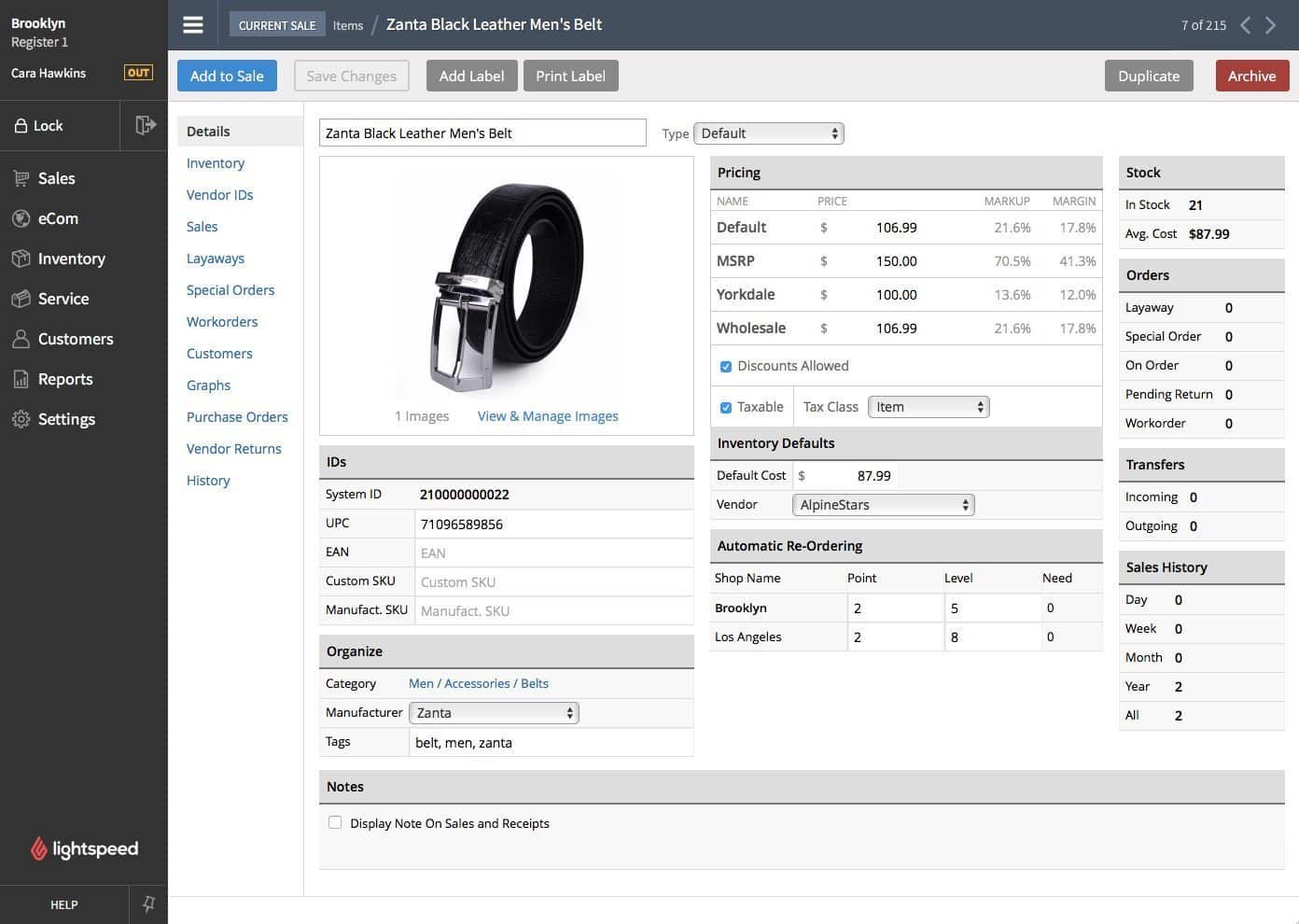

However, as was the case at my store, the best option for retailers is to use a POS system that will keep searchable vendor and product directories.

There are lots of POS systems to choose from, and they all have unique inventory systems. Read our guide to learn more about the best POS inventory systems for your business.

Expert Tip: Build Relationships With Product Suppliers

Even with the best inventory management plan, issues can still arise where you need products ASAP to fulfill an order. When this happens, retailers are at the mercy of their suppliers. If there is a quality control issue or a discrepancy with a purchase order, having a good relationship with your supplier can help resolve these issues quickly.

I was able to build strong relationships with product suppliers by sticking with the same suppliers when I could, meeting suppliers in person at trade shows, and, perhaps most importantly, paying invoices on time.

As sustainability is becoming more critical to consumers and they demand greater environmental efforts from businesses, 53% of businesses are increasing their focus on sustainable sourcing.

Step 3: Create & Submit Accurate Purchase Orders

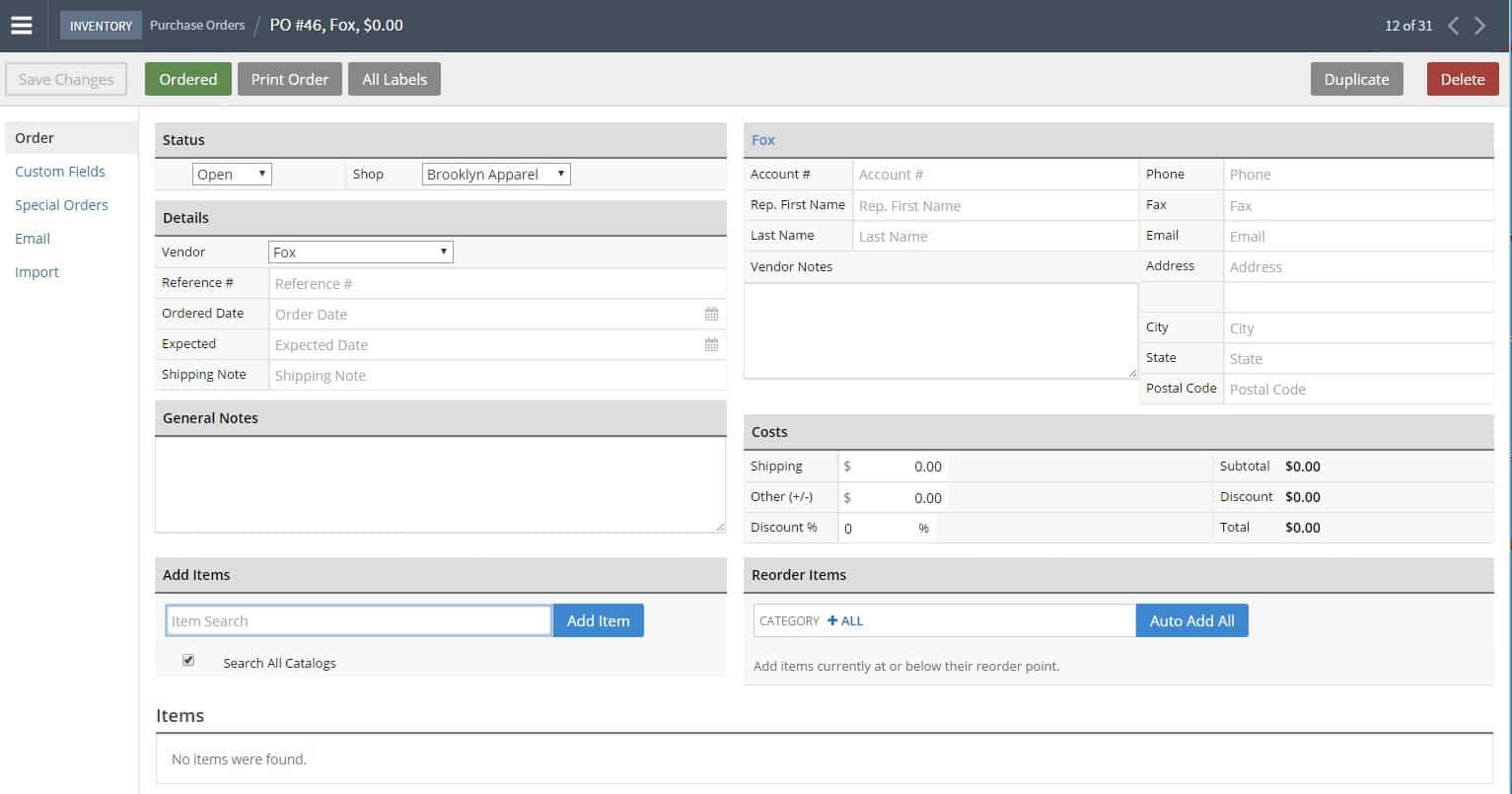

A purchase order (PO) is a buyer-created record of an order that is submitted to the vendor and serves as a legal contract for the sale of goods. You use POs to cross-reference actual goods and invoices received to those ordered and paid for. If there is a discrepancy between your PO and the goods received, you can use your PO to return to the vendor and settle up.

Purchase orders record what you ordered from your vendors and act as a receipt that you can compare to the goods you actually receive.

I submitted my POs to vendors electronically through email or the vendor’s online ordering portal, as is preferred over any paper system. While I didn’t use one at my store, some POS systems, like Lightspeed, have PO features that let you create and manage POs right from your POS system. Some systems even include vendor directories to manage vendor contact information, automated PO creation at set stock points, and receiving tools with POS data built in.

In the news:

As the economy continues to dip and consumer habits become more conservative, the inventory-to-sales ratio is rising, hitting 1.29 in April 2023, with an upward trajectory. This means that for every sale, retailers have an average of 1.29 pieces of inventory. To account for this new economic environment, retailers should slow their purchasing rates to match slowing sales rates.

Step 4: Receive Orders Accurately

Once you have submitted your purchase orders and your suppliers have fulfilled them, you want to be sure that you receive your stock accurately. Supplier error is fairly common, and if you aren’t being systematic about receiving your inventory, you might get shorted, overcount, or underestimate your inventory levels—which can lead to shrinkage (having less product than your records show) and a decrease in your margins.

To ensure the accuracy of my orders, I followed these steps:

- Unpack the shipment and organize items by product.

- Count/scan products.

- Compare the count to your PO.

- If the counts and products match, file as received.

- If you find errors like wrong, shorted, or missing items, note these on your PO and contact your supplier immediately to resolve them.

- Shelve or store all correctly received stock (tag or label first if needed for your system).

- Enter your invoice into your accounting system.

The inventory management system that I used had an accompanying app that turned my phone into a barcode scanner. I could then select “receiving” as the task and scan products, and the app would count and log my shipments for me. This made my life so much easier, so I would suggest looking for a barcode scanning app as a POS feature.

Accurately counting and receiving stock is important for preventing shrinkage and ensuring the accuracy of your orders. (Source: Pinterest)

Did you know?

According to a widely reported stat, only 6% of companies report full visibility into their supply chain.

Step 5: Tag & Label Inventory

Once your products are physically on hand and accounted for, you will need to tag and label them so they are ready for the sales floor and organized internally.

To ensure your tags are ready for both the sales floor and the stockroom, they should include these main things:

- Price: The selling price of your item. All your inventory will need this before it can go out on the floor and be customer-facing.

- Product Labels: You should have some sort of labeling system for your inventory so you can easily organize and track it internally. We recommend using both a barcode label—so you can easily scan items in your inventory system and at checkout—and a descriptive written label, like “red shirt” or “child’s leggings,” that corresponds with where the item goes in your store and in storage.

Learn about the different types of labels you can use for your products to keep them identifiable and organized with our guide to UPCs and SKU numbers.

Regardless of the type of labels you use, a good time to tag and label inventory is during the stock receipt process. This ensures the task isn’t overlooked and prevents the unlabeled stock from being shelved or displayed for sale.

Once printed, labels should be fixed directly to the product. Some inventory might even arrive prelabeled with the manufacturer’s barcodes, description, and price. If you aren’t using an internal labeling system, this makes your job easy. You can just start organizing.

Use our guide on how to create barcodes (plus a barcode generator) and check out our picks for the best barcode label printers to get started labeling your products.

Step 6: Organize Your Stockroom or Warehouse

Having an organized stockroom will not only make things easier to find but will allow you to fit more merchandise and keep better tabs on your inventory. I remember taking the first week at my store to completely reorganize the stockroom to improve its functionality and make my life 10 times easier.

In retail stores, tall storage shelves or double-tier hanging racks can maximize your wall space while allowing movement and easy access. Additionally, storage bins can be stacked and labeled on the ground to use floor space efficiently.

In larger warehouse settings, there is typically more room to store goods within aisles that have built-in shelving and hanging storage. The biggest thing you will want to ensure is that you choose storage devices that make sense for your merchandise and can change over time.

For example, my store had a very small storage room, so we used lots of hanging racks and stacked bins to maximize the little space we had. The racks were easy to roll, and we could label them any way we needed with rack tags. Similarly, the bins were great for our heavier/knitted items that took up too much hanging space or couldn’t be hung, and were easy to label, depending on the inventory we had on hand.

Whatever your method, your stored inventory needs to be well-organized, clearly labeled, and accessible for pulling and inventory counts. This can be done using the boxes goods come in, stacking bins, or even hanging separators for hung apparel.

Utilize your wall space to fit as much product as possible in limited space. (Source: Pinterest)

Do you use a warehouse to store your products? Learn how to keep your warehouse operation efficient with our guide to warehouse layout design planning.

Step 7: Track Inventory in Real Time

Tracking your inventory levels in real time is key for keeping the right items on the shelves in the right quantities—i.e., good inventory management. Whether by hand or through your POS system, a sound inventory management system records every sale in detail and adjusts inventory levels as each item is sold.

There are some great inventory management software that you can use to get real-time updates and stay on top of your inventory. Learn more about the top products on the market with our guide to the best inventory management software.

While you can use a spreadsheet for inventory tracking, I used a POS system with integrated inventory management. My POS system tracked inventory levels in real time and adjusted quantities with every sale. Then, as my inventory numbers would dip below my designated safety stock level, I would get automatic low-stock alerts and PO generation for the low-stock items.

A POS system will make tracking inventory levels and reordering your supplies quick and easy and, most importantly, will base your inventory levels on actual sales, not on your best guess.

Step 8: Conduct Regular Inventory Counts

I used to believe that inventory counts were unnecessary if you had a POS system keeping tabs on your inventory levels. Physical inventory counts can be mundane and tedious, so why not defer to technology?

The answer: Technology isn’t always 100% accurate, and it can’t account for products lost to shrinkage. Getting into your stock room and actually counting your products is the only way to know exactly what you have, allowing you to settle disparities between actual levels and those on your POS and manage your stock accurately.

Most small businesses do a full inventory count once each year for tax purposes but will also perform smaller partial inventory counts, or cycle counts, throughout the year.

Here are the types of counts you should perform to ensure you have an accurate eye on your inventory:

The basis of both annual and cycle inventory counts is your current Quantity on Hand (QOH) or the amount of inventory you should have in stock for every item you carry. The formula for QOH is as follows:

QOH = (Previous QOH + Received Inventory)-Sold Inventory

Your QOH is the number you will measure your annual and cycle counts against. So, for example, if I thought I should have 272 packs of gum based on my QOH calculation, I would be looking for 272 packs of gum in my cycle or annual count. If I found a discrepancy, say only 250 packs of gum, that would indicate an error or theft that I could then look into further.

Annual inventory counts are a complete inventory count, typically done at the close of each fiscal year for income tax purposes. These counts give you an overall picture of how much inventory you have on hand at the close of your year. They can also help businesses uncover inventory shortages due to miscounts, shrinkage issues, misplaced stock, and/or receiving errors.

While most retailers perform more frequent counts, some small businesses with limited staff or small inventories will only perform this type of inventory count each year. While annual inventory counts are a good practice regardless, by year’s end, it’s too late to fix most of the problems they reveal. To catch inventory issues before they become costly, you’ll also want to conduct periodic counts, called cycle counts.

Regular counts will also help you understand what stock is not moving and might need to go on sale to avoid incurring greater carrying costs (the expenses a small business must pay to hold and store unsold merchandise).

Cycle counts are periodic spot counts that take inventory of specific categories or subsets of products. For example, at my boutique, we would do a couple of cycle counts each week for different types of clothing—basics T-shirts one day, jeans another, earrings the next. Cycle counts helped us see how specific products were performing and determine whether it was time for a restock.

Typically, you perform cycle counts on a regular basis. So, you might decide to count shirts every other Wednesday and jeans every two months. As a best practice, you would cycle count all of your products daily to keep a good grasp on their levels. Without the right tech and staff, however, this is next to impossible. Schedule your cycle counts based on the speed with which you move through your inventory, with items that sell faster getting more frequent counts.

When it comes to how you count your inventory, you have two options. You can either do it manually or use a POS system to automate your processes. Here, we will look at both:

Step 9: Reconcile Discrepancies

Ideally, your physical inventory counts will match your projected quantities on hand (QOH). However, in my experience, this is seldom the case, and there are frequently differences you have to reconcile. If you count more or less of a product than you anticipated, you will need to investigate the discrepancy to figure out where things went wrong.

There are two primary reasons for inventory shrinkage. Either there has been a clerical error, or theft has occurred. Sometimes, clerical errors are not actual losses—an item could have been misplaced or a key mistyped. Other times, shrinkage indicates actual loss, and you should investigate where it happened so you can work on preventing shrinkage in the future.

As retail theft increased (and continues to do so), retail shrink was worth $100 billion in 2022. Learn how to prevent theft with our guide to retail theft prevention strategies.

If you determine that your missing merchandise is truly gone, you should adjust your QOH in your records or inventory management system/POS. After that, you need to record the dollar value lost due to the shrinkage in your inventory.

Inventory Management System Quiz

Thinking you want to automate your inventory management and use software instead of a manual application?

Inventory Management Frequently Asked Questions (FAQs)

Expand the questions below to get answers to some of your most asked questions about inventory management.

Inventory management is the process (or all the processes) involved in keeping the right products, in the right quantity, in stock at the right times. In other words, inventory management is anything you do to avoid stockouts and to have in-demand products in stock for your customers to buy when they want them.

Overall, our top pick for inventory management systems for small businesses is Zoho Inventory. For retailers specifically, however, we recommend Lightspeed.

To do inventory management, you first need to organize your existing products and vendor info, place purchase orders, receive your orders, tag and label new inventory, organize it into your storage area, and then continually track and count inventory over time so you can monitor when it is time to place new orders or put items on sale.

Small business inventory management involves using a spreadsheet and tracking by hand or with an inventory management software solution to automate the process—and it isn’t very different for larger companies. We suggest Square as a free option that is perfect for small companies. Learn how to use Square to manage your business.

Bottom Line

A good inventory management system means that you always have an accurate picture of your stock so that you can avoid waste and provide the merchandise and experience that your customers expect. Whether you’re looking to learn the basics of how to organize inventory for small businesses or reinvigorate an existing system that has become disorganized, these steps will help you set up and streamline your operations.