Counting your bar inventory—the total supply of beer, wine, spirits, mixers, and other beverages that your restaurant or bar has on hand—is the most important aspect of running your business after providing a great guest experience and working environment for your staff. Understanding what you have on hand, where the product is going, how much it is costing you, and where you can gain savings is fundamental to operating a successful bar.

The cost you calculate from this liquor inventory can be known as either bar cost or liquor cost, but generally means the cost associated with the goods you have used operating a bar.

There are two main ways to manage your bar inventory: using an inventory app or using spreadsheets. This article will break down how to perform your bar inventory counts using either system, giving you the foundation you need to start managing your bar cost and the goods you serve.

Step 1: Decide What to Track

Deciding what to track depends on the different types of liquor you have on hand and in inventory. This will also take into account any bar-specific garnishes and nonalcoholic items. This could be Luxardo cherries for a Manhattan or tonic water for a gin and tonic. Any other beverage item that you will use in your bar program goes into this inventory count.

The best way to track a bar inventory is by using the FIFO method, which stands for “First In, First Out.” This method simply means you will use the older products first, ensuring they are used before the expiration date and that multiple items aren’t open and losing their quality over time.

Deciding Who Will Track Bar Liquor Inventory

Just as important as deciding how you will track your inventory is designating who will actually count it. This task is often done by workers in some sort of leadership role. For a smaller team without many leadership levels, you can have your employees help take part in the tracking. But a high-level leader of your business should be reviewing inventory counts on a monthly basis. This is to ensure it is being done correctly and items are adding up and to give a true understanding of the bar’s cost of operations.

Many inventory software tools offer online training materials to help you get up to speed with their system. Use these tools you are paying for to help train any staff in charge of inventory tracking.

Step 2: Set Up Your Tracking Method for Liquor Inventory

As mentioned before, there are two main ways to take your bar inventory: using an app or using a spreadsheet. Let’s break down how to use both to take accurate inventory counts.

Setting Up a Spreadsheet

Using a spreadsheet is how many operations still work within the food and beverage industry, as they are efficient and organized ways to take bar inventory. A spreadsheet for inventory should be easy to read and use so that information can be collected accurately and in an efficient manner. Planning with your managers is key when using a spreadsheet so that everyone is on the same page on how to use it.

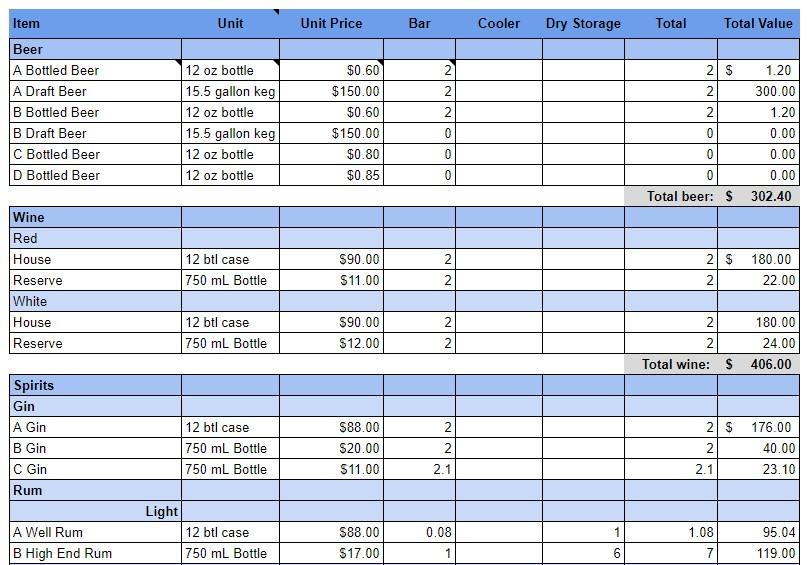

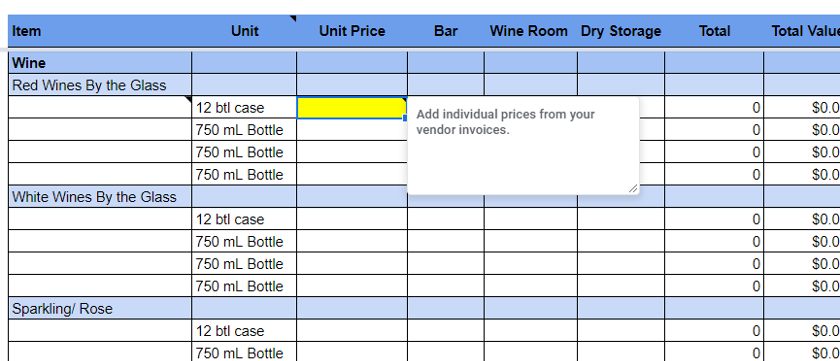

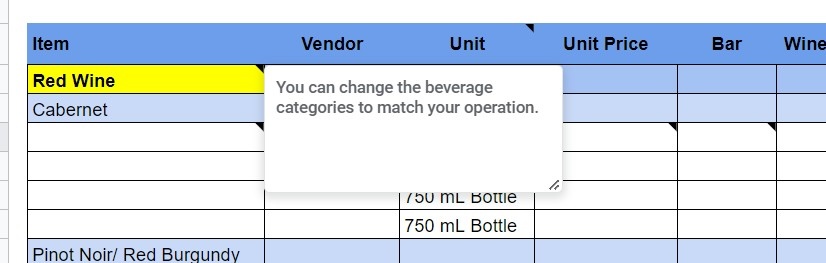

The sheet you create needs to include product information, like the price and the unit size, and an accurate product description. Arrange your sheet in categories: beer, wine, spirits, and nonalcoholic beverages.

Save time creating your bar inventory spreadsheet by checking out our bar inventory spreadsheet templates.

Arrange your spreadsheet by beverage type so you can enter information quickly.

Setting Up an Inventory App

Inventory apps are used to order products and count them, saving you time, reducing errors, and giving you more detailed reporting faster than a spreadsheet system. With the technology available on the market, liquor inventory is easier than ever. You’ll start by adding your vendors, items, and storage locations to the app. In most cases, you can bulk upload your vendor and item information from spreadsheets. Alternatively, you can add items one by one.

There are a variety of apps out there to use, but the best restaurant inventory management software streamlines your information and organizes it in a way that makes the data accessible and usable. Another way of tracking inventory is by using your point-of-sale (POS) system and its built-in features. Some of the best POS inventory systems are built to not only organize your data but also place orders through specific vendors.

Many liquor inventory apps will allow you to import your system of tracking, making a seamless transition from your sheets to their app.

Whether you upload items in bulk or one by one, you’ll need to include:

- Item name

- Storage location (may have multiple locations)

- Vendor you purchase from

- Product code from vendor

- Price

- Unit of measurement (bottle, case, ounces, etc.)

- Number of items in a pack

- Item category (beer, wine, liquor, nonalcoholic beverage, etc.)

When adding your vendors, be sure to include your sales representative’s name, phone number, and email address, along with order minimums, cutoff times, and delivery days. This way, anyone on your team can place an order or reach out to the sales rep if problems arise. I always suggest having your reps organized in your phone or work phone by name and company for ease of access. That way, you can find whoever you need, regardless of how busy you may be in your business.

Lastly, when setting up your inventory app you will need to set up count sheets. These sheets will serve as the basis for your inventory counts and will organize your information throughout the inventory tracking process. You should have a sheet for each storage area that you keep your goods in and set your items up in the order they will appear on your shelves.

Using a spreadsheet like ours helps you break out data to fit the categories your specific liquor inventory falls into.

You can typically include multiple units of measurement like “case” or “bottle” for each product directly on the count sheet—so you won’t have to wonder if that “1” means “1 case” or “1 bottle.”

If you count high-value or high-volume items daily, create a separate count sheet for daily counts. This makes it easier to perform off-cycle counts while still keeping tabs on expensive and popular spirits.

Step 3: Do an Initial Count

Your initial count of inventory needs to be done outside of normal business hours. This is so you give yourself the time and space to count your inventory while having everything in place to get an accurate assessment of what is on hand. It is impossible to do a bar liquor inventory while drinks are pouring, so these dedicated times outside of business hours are key.

With spirits in particular, it is a good idea to have multiple storage locations in your establishment, most of which remain locked. Because of its high cost and potential for dependency, liquor is highly prone to theft.

Below are some best practices when it comes to counting your bar inventory:

Count When the Bar Is Closed

As mentioned above, counting when the bar is closed is the best time to ensure accurate counts during your inventory tracking process. This is usually done by one or more managers, which then can evenly distribute sections of the establishment to count during this time. Counting when the bar is closed gives you the focus you need to get accurate data and also lets you see your inventory as a whole without the bustle of service.

Spread the Workload

While a manager should lead inventory counts and oversee the collection of data, using apps or multiple spreadsheets throughout your bar allows for more people to take on smaller amounts of the inventory counting process. As long as the proper training is in place, this makes the process more efficient and data collection easier.

Count Before Pending Deliveries Arrive

You need a static inventory count to compare to invoices for the same time period. Your sales and costs need to be in the same timeframe, so a strict cutoff point is important. It is easiest to just avoid scheduling deliveries for days that you are counting inventory.

Count in Pairs

Two sets of eyes better ensure accuracy. More than anything, however, counting in pairs prevents potential theft—or the appearance of it. Beyond this, it allows you to double-check work and make sure that counts are as accurately recorded as possible.

Use the Same Team to Count Inventory

At every inventory interval, schedule the same team to perform the physical count; they will get faster and more efficient.

Ensure All Staff Knows Common Counting Practices

Each bar may use different verbiage and have different brands. Ensure all staff doing inventory counts know exactly what they are looking for. Also, be sure to signify if you are counting the amount in a bottle (½ bottle vs ⅓ bottle) or just assuming it is a whole unit. These details need to be known by the entire inventory tracking team before counts are done.

Audit Your Process

If you have the ability to do so, have an outside auditor engage with your process. If you are an owner of a bar and have managers doing this count, audit them on occasion. An outside auditor for a larger restaurant group can be someone in accounting who works with the inventory. A person with an interest in ensuring the accurate count is taken will help negate inflating or falsifying numbers during an inventory count process.

An audit might seem like a lot of work, but occasional audits are how large bar and restaurant operations stay profitable. In a bar or restaurant, a manager’s success (and sometimes their salary) rides on profitability and low costs. Fudging the numbers does happen, and that’s why an auditor should be considered.

Step 4: Set a Consistent Cadence

A good cadence to stick to when doing your inventory counts is weekly. Slower days, such as a Monday, are ideal as this allows you a good amount of time to organize the count and input the data you gather from it. Weekly counts allow you to get a consistent read on usage and par levels and allow you to adjust quickly if any irregular patterns arise during your inventory analysis.

Weekly inventory accounts may feel aggressive at first, but over time, it will give you 52 data points per year to show just how much of each product you use. It gives you the option to catch any instances of theft, overuse of products, or even unrecorded waste.

This all culminates in an end-of-the-month report that most food operations conduct. This will show how profitable you were in a given month and how much money you spent. Bar inventory and inventory of goods as a whole are how you get an accurate number.

Step 5: Calculate Inventory Usage & Generate Reports

When using sheets, you need to input your information and calculate it at the end of the month. Your inventory count isn’t complete until you collect and input all the required data. The first step toward analysis is adding your total purchases and your total sales, separated by product category.

Total sales can easily be found through your POS reports, while total purchases will come from your invoices for orders you placed between inventory counts. If you perform inventory counts monthly, you’ll need all the invoices from the preceding month.

Save time by recording your sales and purchases on a daily basis. Make it part of your closing managers’ duties to enter each day’s sales and invoices in the appropriate section of your spreadsheet file. This will save you time on inventory day and help you see patterns in sales and ordering.

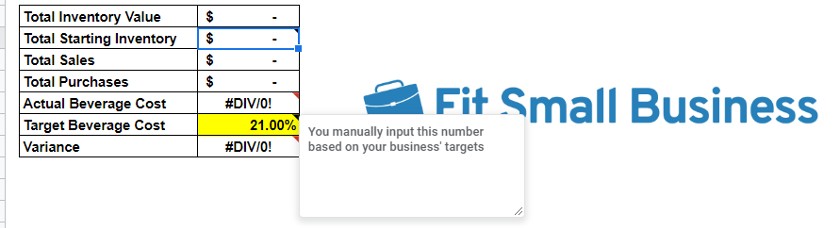

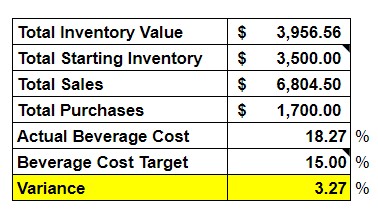

Our inventory spreadsheet is also able to let you zero in on target vs actual cost so you can see the variance and record over time how you are doing.

For inventory apps, your counts will generate an automatic report. You will be able to select the time period in which you wish to see the counts completed. From there, you can also see the amount spent and sales as long as you are tracking your purchasing and sales data correctly through the software.

If your inventory app integrates with your POS system, you’ll get even richer information based on your sales data. This allows you to quickly see if you have missing inventory. If you bought items and didn’t sell them or count them, then you could have a problem with theft, breakage, or spoilage.

Step 6: Analyze Costs & Adjust

The standard liquor cost for a bar should sit somewhere between 18%–24%. This is to leave room for food costs, labor costs, overhead, and other expenses. Hitting this target plus other cost percentage targets in your business allows you to make a profit. Below is a breakdown of the cost per type of alcohol you should be hitting based on our experience and general industry knowledge.

Industry Standard Liquor Cost %

Type of Good | Liquor | Beer | Wine | N/A Bev |

|---|---|---|---|---|

Cost Goal % | 15%–20% | 20%–30% | 30%–40% | 10%–20% |

How to Find Liquor Cost

To figure your actual beverage cost, the math is easy; you just divide your total cost of goods sold (COGS) by your total sales:

(Total Beverage Cost of Goods Sold) ÷ (Total Beverage Sales) = Actual Beverage Cost

You can program your spreadsheet with the formula so your costs and variance will automatically populate as you update your inventory. You’re likely to always have some variance from your target. But, so long as your variance is no more than 2% to 3%, your bar is doing fine.

Cost of Goods Sold: Cost of Goods Sold (or COGS), is a very helpful accounting term. This figure takes into account your existing inventory along with the purchases you made within the inventory timeframe. Using your COGS number to figure your bar inventory costs ensures accuracy. The basic COGS formula is:

(Existing Inventory Value + Purchases) – Current Inventory = COGS

Making Sense of Your Counts

Adding beverage cost formulas to a spreadsheet simplifies complex calculations so you can see your bar performance at a glance.

As you can see in the image above, once you have all of your data, you can calculate not only your cost but the variance against your goal. This then gives you room and insight into where you need to be tighter on inventory and what operational fixes you can make in order to hit your beverage cost targets.

Tips for Bar Liquor Inventory Control

When taking your liquor inventory, follow the tips below to ensure an efficient process and accurate counts.

Review Prices From Vendors, Invoices & Changes

Being aware of the pricing your vendors give you and how much you are being charged is key to ensuring that no outside force is affecting your profitability as a business. Consistent pricing updates, price comparisons, and vendor communication are keys to getting the best rates. Additionally, having an organized system for receiving and storing invoices is important.

Ensure Staff Is Trained Properly

One of the biggest ways bars lose money is improper training or mismanagement of staff. Ensuring staff follow all standard operating procedures (SOPs) and work in an ethical manner is how you manage your liquor costs. Are staff members pouring drinks correctly? Are they giving out free products? Are they themselves drinking on the job? Ensuring a tight and clear environment where staff is empowered and understands the rules of your business is how you prevent labor from affecting cost.

Receive Products Properly

Thorough inspection of all product packaging is needed to keep bar inventory under control. This means rejecting any broken bottles, busted cans, or other items that are compromised and unusable. This also lets you ensure all products can be used in-house, and money is not wasted on items you did not damage. This comes through diligent receiving and knowing what to look for when you receive these products.

Have Organized Storage

Storing your goods in an organized and clean manner affects not only food safety but also how easy you can do your inventory counts. If your goods are scattered in every which way, counting will be a nightmare. Ensuring bottle labels are facing out and rows have the same number of items and having designated storage for specific goods will make inventory counting a breeze.

Dig Deep Into Variances

If you see a variance in your data, you need to address it. Recounting to be sure the data is accurate should be the first step. If a variance is still showing, explore further.

- Are your staff members improperly measuring drinks? This is a perfect time to retrain them.

- Are bottles of a certain liquor missing every few months? Theft could be an issue.

Collecting data is only half of the issue. If you see a variance, addressing it is urgent so you can improve your cost percentage and profitability.

Frequently Asked Questions (FAQs)

These are some of the most common questions people ask about how to do liquor inventory.

Bars and restaurants should perform a physical inventory count at least monthly, though many of the top bar programs choose to perform weekly inventory as a standard operating procedure. Weekly inventories give you a deeper sense of how efficiently your bar program is operating than any other change you make. We highly encourage weekly counts for the most accurate representation of your bar’s inventory and financial health.

Pour cost is the most common term you hear in bar-only inventory. In bars that operate within restaurants, you more frequently hear “beverage cost.” They both mean the same thing; the amount of money you spend to make a beverage, expressed as a percentage of sales. Just as with any food and beverage category, you can figure individual pour costs of a single cocktail, or you might refer to your overall beverage cost number as your bar’s pour cost.

The best way is via an inventory app or a spreadsheet. Either system can be tailored to match your storage areas and unique bar supplies, which will speed up your inventory counts.

If counting with an app, you can record counts on a smartphone or tablet. If using a spreadsheet, it is best to print a physical copy of the spreadsheet, record counts in writing, and then enter the counts into the spreadsheet program on your computer.

Apps record each entry, so it is easier to spot counting errors. You can also typically see exactly who performed the count in the app, so you know who to contact with questions. If you use spreadsheets to track your inventory, the written count sheets are your backup. So you can reference them if there is a question or a discrepancy.

There are two ways to measure partial bottles during inventory counts: visually by tenths or physically by weight. To measure by tenths, you visually divide the bottle into 10 equal sections. Then when you count the bottle, record the bottle’s fullness to the closest tenth. So if a bottle is half full, you would record 0.50 (or 5 out of 10) on your inventory sheet.

Some inventory apps will scan partial bottles with a smartphone camera and automatically generate the volume. This is, essentially, just automating the tenths of a bottle system. Alternatively, you can weigh each bottle on a scale to count it. This can be a little fussy because you have to subtract the weight of the bottle (which varies by beverage type and brand).

A well-managed bar program can expect to make 30% to 40% profit on spirits after costs and expenses are accounted for. An individual bar may be different, however, as the costs of liquor licenses and rent vary widely based on location.

Physical inventory counts are the gold standard of bar inventory. Your inventory app will save you time in counting and analyzing your inventory, but if you want to spot breakage, theft, or spoilage, you absolutely must perform physical counts.

Bottom Line

As you can see by now, bar inventory is integral to operating a profitable business. Knowing where you are financially hinges on the data that bar inventory provides. Using the methods above will give you the information you need to understand where your business is financially and how to make it better. Whether you are using Excel sheets or an app, these steps will give you the best operating practices to track inventory for your bar.