A supply chain is a network of people, companies, and processes working together to create and deliver products or services to customers. The supply chain landscape is evolving rapidly, driven by market growth, sustainability demands, disruptive forces, and technological advancements.

In this article, we cover 23 supply chain statistics, current supply chain and retail trends, and recent insights to help you better understand and navigate the dynamic world of supply chain management in 2025.

Key Takeaways:

- Market Growth: The value of the supply chain management industry is projected to reach $30.91 billion by 2026.

- Sustainability Surge: 42% of companies are using technology to embrace greener supply chains, with a focus on electrification and resource management.

- Disruption Causes: Recent supply chain disruptions were mainly caused by inflation, talent shortages, customer demands, limited insight into customer behavior, and supply chain shortages.

- Geopolitical Turbulence: While global trade is more accessible than ever, it’s also becoming more restrictive. Costs are rising, and there were 3,000 new global trade regulations introduced in 2023 alone.

- Autonomous Future: 45% of supply chains are set to go mostly autonomous by 2035, driven by increased tech investments in 2023 and beyond.

General Supply Chain Stats and Trends

1. The global supply chain management market reach $30.91 billion by 2026

According to data from Statista, the supply chain management market has steadily grown from $15.85 billion in 2020, and is expected to reach $30.91 billion by 2026.

2. 45% of businesses have limited supply chain visibility

A McKinsey survey found that 45% of respondents either have no visibility into their upstream supply chain or can see only as far as their first-tier suppliers. This lack of visibility often leads to disruptions, inefficiencies, and challenges in managing inventory.

3. More than half of supply chain leaders are investing in technology and innovation

According to the 2024 MHI Annual Industry Report, 55% of supply chain leaders are investing in supply chain technology and innovation. Of these respondents, 88% plan to spend over $1 million while 42% plan to spend over $10 million. Investments are mostly focused on supply chain resiliency, transparency, and combating workforce shortages.

4. Over half of businesses name cybersecurity as the biggest concern for supply chain resilience

A BCI survey found that 55.6% of businesses’ main concern for future supply chain resilience is cyber-attacks and data breaches, followed by adverse weather, natural disasters, and energy scarcity.

5. A staggering 93% of businesses are quantifying supply chain risk

Though it was about five years ago, professionals have learned a lot from the supply chain crises during the COVID-19 pandemic. As a result, 93% of businesses are now taking steps to quantifiably measure and analyze supply chain risk, a McKinsey survey found. In fact, 71% have the capabilities to do this in-house.

Despite this heightened awareness of supply chain risks, less than half (47%) regularly report supply chain risks at the board level, and only 10% have budget allocation for risk management. In fact, only 20% of professionals believe supervisory boards thoroughly understand supply chain risk.

6. Price inflation is the top supply chain challenge

Businesses ranked their top five supply challenges for MHI’s Annual Industry Report:

- Price increases from inflation: 53%

- Talent shortage: 52%

- Customer demands: 51%

- Insight into customer behavior: 50%

- Supply chain disruptions and shortages: 50%

Supply Chain Disruption Statistics

7. Most businesses have had significant supply chain challenges over the past year

Though the COVID-19 pandemic is no longer wreaking havoc on supply chains, most businesses are still faced with challenges of disruptions. According to the McKinsey survey, another 44% say their supply chain footprint has given them major challenges, requiring significant business changes. And 49% say disruptions have caused significant planning challenges.

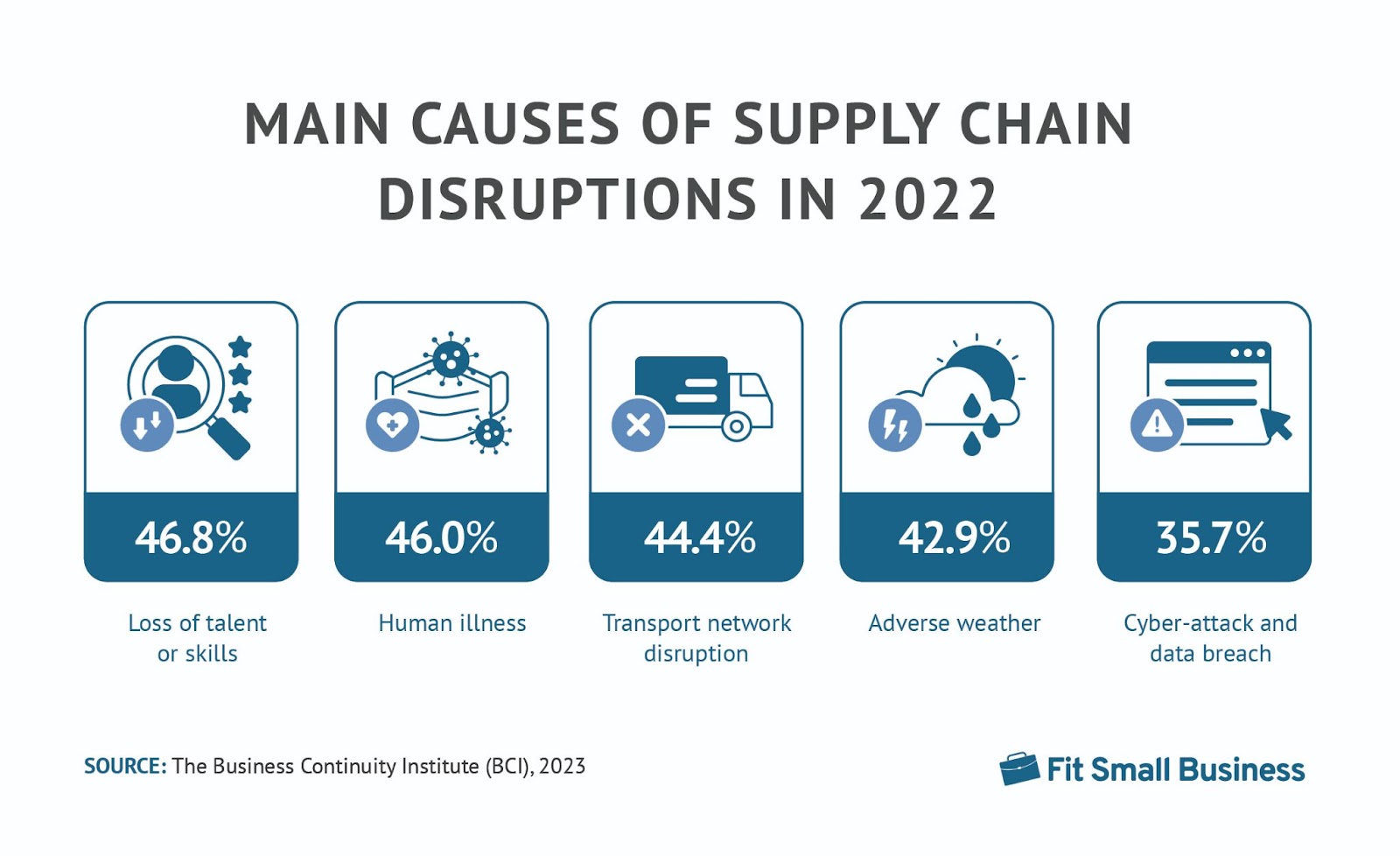

8. The main causes of supply chain disruptions are loss of talent/skills, human illness, and transport network issues

BCI reports that the main causes of supply chain disruptions are loss of talent/skills, human illness, transport network issues, adverse weather conditions, and cyber attacks or data breaches. Many businesses are faced with these supply chain issues.

9. About 40% of Asian manufacturers will implement multi-shoring to reduce disruption risk

By the end of 2024, IDC predicts that roughly 40% of manufacturers in Asia will broaden their supply strategies, sourcing from various locations (multi-shoring) to better control the risk of disruptions. This change is projected to enhance their supply dependability by 15%.

Supply Chain Technology Statistics

10. Just over three-quarters of companies have APS systems

McKinsey also found that 76% of companies have implemented an advanced planning system (APS). Of those, 59% say their planning processes require little manual workarounds, compared to just 4% of companies without APS. Still, about four in 10 APS users say the technology requires too many manual interventions. Another 37% say their APS systems haven’t been adopted widely enough across the business.

11. Over 40% of companies use technology to make supply chains more sustainable

Amid environmental sustainability concerns, 42% of companies are using to technology to enable them to be more sustainable and environmentally conscious in their supply chains, according to MHI research. This aligns with the global push for greener operations, emphasizing reduced carbon emissions, responsible sourcing, and increased use of alternative fuels in shipping.

12. 39% of businesses use AI technology in supply chain management

The same research found that AI technology has been implemented by 39% of businesses looking to optimize supply chains. But it’s not replacing humans. In fact, many are investing in “human-centric technology strategies,” while relying on AI to help with decision-making. Many are seeing the best solution to be a hybrid of human thinking and AI technology.

Most (51%) believe AI will give them a competitive advantage within the next 10 years, while only 16% are unlikely to implement AI within the next five years

13. 4 in 10 organizations use technology to report on supply chain disruptions, with Excel being the most popular tool

Forty percent of businesses surveyed by BCI stated that they use tech to record, measure, and report on performance-affecting disruptions in the supply chain. Among them, Excel spreadsheets, incident response data, and financial models are the most popular.

14. 45% of supply chains are expected to be mostly autonomous by 2035

Based on one EY research report, it’s estimated that 45% of supply chains will be largely autonomous by 2035, incorporating technologies like robots, driverless vehicles, delivery drones, and automated planning systems.

15. 37% of businesses already use automation and AI to improve supply chain efficiency

In the same poll, 37% of supply chain executives stated their business already uses automation, AI, and machine learning techniques to enhance their supply chain, while another 36% are planning to implement them soon.

Outsourcing Supply Chain

16. 66% of companies are exploring nearshoring

While outsourcing supply chains to countries across the globe was a common strategy until this point, more businesses are exploring the idea of outsourcing to nearby suppliers—nearshoring. According to McKinsey, two-thirds plan to source supply chain partners who are located more closely, especially when it comes to the automotive and consumer goods industries.

Another 64% of businesses are actively regionalizing supply chains, a 20% increase from 2023. Of the 50% of companies that use supply chains from another region, 89% want to reduce that. This trend is especially prevalent in Europe and Southeast Asia.

17. 8% of businesses have in-house resources to support digitization

Per McKinsey, while many businesses want to reduce their dependence on outsourcing, only 8% have the internal resources to implement their digitization and growth goals. Yet it seems companies don’t know how to improve this. Over the past three years, 27% fewer companies are actively investing in internal skill development—and outsourcing to external hires has increased by 15%.

Inventory Management and Supply Chain

18. 85% of companies will use technology to optimize inventory

Over the next five years, MHI predicts that 85% of companies will use inventory and network optimization technology. The same amount of businesses are expected to implement AI and Internet of Things (IoT) technology to improve supply chain management. Other technologies expected over the next five years include sensors and automatic identification (83%), robotics and automation (83%), cloud computing and storage (81%), 3D printing (81%), and advanced analytics (78%).

19. Increasing safety stock is a top strategy for most businesses

Many businesses have risk mitigation top of mind. One way companies mitigate risk is by increasing the amount of safety stock they carry. In fact, 78% of companies do so, according to McKinsey data. Another top strategy is to implement dual-sourcing for important raw materials and supplies.

20. 25% of businesses are actively trying to reduce stock levels

While many are increasing stock levels to mitigate risk, a quarter of businesses are also actively lowering their stock levels, according to the same study. This is because they expect stocks to drop below COVID-19 shortage levels.

Future of Supply Chain

21. Changing water levels impact global trade

The Panama Canal is an important global trade destination, allowing 8% of the world’s shipping containers to travel overseas. However, low water levels have impacted its ability to handle such traffic.

Costs for the Panama Canal to run and operate are estimated to increase to between $500 million and $700 million in 2024, significantly higher than previous estimates of $200 million. Plus, new fees have been introduced, making global trade through this route more expensive than before. Global trade is getting more costly for a number of reasons.

22. Trade restrictions are changing the landscape

New global trade regulations are introduced every year. Notably, global trade restrictions have been on the rise. There were just 650 new restrictions in 2017, while 2023 saw more than 3,000 new restrictions introduced.

23. Nearly 80% of retailers are gaining more visibility with end-to-end dashboards

Technology is top of mind across the retail industry, and supply chains are no different. Nearly 8 in 10 businesses were implementing end-to-end dashboards to give them full visibility into their supply chain and related metrics in 2023, per McKinsey data. This is a significant jump from the 37% that had done so the year prior. About 71% of businesses expect to change their existing planning processes and governance over the next three years.

Frequently Asked Questions (FAQs)

These are some questions we frequently encounter about supply chain stats.

A supply chain is a network of people and companies collaborating to create and deliver a product. It involves different stages, starting from the producers of raw materials and ending when the finished product reaches the consumer. Supply chains often operate globally, connecting people and organizations worldwide.

Supply chain processes vary based on industry, product type, and business models. The general supply chain steps are 1) sourcing raw materials, 2) refining the raw materials to create basic parts, 3) assembling the parts to produce finished products, 4) consumers purchasing the products, and 5) delivering the products to consumers.

Supply chain statistics are gathered through surveys, data analysis, collaborations with partners, market research reports, and government data. These methods provide insights into supply chain performance and trends.

To enhance your supply chain, key strategies include improving visibility, optimizing inventory management, strengthening supplier relationships, streamlining logistics, embracing technology, and managing risk.

Bottom Line

The supply chain landscape is still stabilizing from the impact of the COVID-19 pandemic while undergoing new transformations due to market growth, sustainability concerns, disruptions, and emerging technologies.

These supply chain statistics can help equip you with the knowledge to better understand the supply chain industry and navigate evolving supply chain trends. If you’re ready to strengthen your own supply chain, learn more about order fulfillment strategies, third-party fulfillment centers, and our top recommendations for third-party logistics (3PL) services.