A fulfillment center is a third-party service provider that manages inventory, processes orders, and ships packages for other businesses. The term fulfillment refers to all supply chain functions related to receiving, processing, and delivering customer orders.

For many ecommerce retailers, the strain of handling fulfillment operations in-house leaves them at a loss for crucial resources like space and time. Fortunately for merchants, wholesalers, and manufacturers, these tasks can be outsourced to third-party fulfillment partners—effectively freeing up their precious time and resources to put toward driving growth in other areas.

Read on to learn more about fulfillment centers and how they work.

What Is a Fulfillment Center?

Fulfillment services are used by retail and ecommerce businesses to take the labor-intensive tasks involved in fulfillment and distribution off their hands. They also enable sellers to keep their merchandise close to their various customer bases without the need to relocate their main operation, thus helping increase shipping speed and decrease cost.

They’re usually located in large buildings equipped with industrial shelving, loading docks, trained staff, and multiple packing areas stocked with shipping supplies. This enables them to receive and store bulk quantities of product from many different sellers, which is then efficiently packed and shipped when each order comes.

Unlike traditional warehouses, fulfillment centers feature shelving for storage as well as packing stations for order preparation.

(Source: Amware Fulfillment)

The most well-known fulfillment provider is FBA (Fulfillment by Amazon), thanks to its massive global footprint of 185 fulfillment centers around the world. But you don’t need to be an Amazon-scale business to hire a fulfillment center; there is a wide selection of fulfillment companies in each state that work with sellers of all sizes.

Fulfillment Center vs Warehouse

Both fulfillment centers and warehouses are involved in supply chain logistics, but their operations are different. To add to the confusion, fulfillment centers are sometimes referred to as ‘warehouses’ because they share similar purposes and features—such as their storage implements and industrial equipment.

>>A traditional warehouse is used to store bulk goods for long periods of time. It isn’t staffed with employees that pick, pack, and ship orders, and your inventory may not be immediately accessible. Warehouses can sometimes be used for B2B distribution.

>>A fulfillment center is designed to store inventory for short periods of time (typically a matter of weeks) and keep it immediately available for customer orders. Additional staff and equipment are present to receive orders, package them, and ship them out quickly.

How Do Fulfillment Centers Work?

Each step of the fulfillment process is important to ensure your orders go out smoothly and your customer experience remains positive.

Some merchants—especially as they’re just starting an online store—find that these tasks can be efficiently performed in-house. But when order volume outgrows available space, labor, and time, it makes sense to hand those duties off to a partner company.

Here is an in-depth look at the six steps involved in how order fulfillment centers work.

1. Inventory Is Delivered to Your Fulfillment Center

The first step in working with a fulfillment center is getting your inventory to them.

If you purchase goods for resale, your orders can simply be routed from your supplier directly to your fulfillment center. Then, when a stock shipment is en route, you’ll forward the details of the shipment to your fulfillment partner. Often, your purchase order or supplier’s order confirmation is all the fulfillment center needs to properly receive the shipment.

If you manufacture goods in your own facility, you’ll ship stock to your fulfillment company yourself via truck freight or parcel shippers like UPS or FedEx. Shipment details are provided when you notify the company of the inbound delivery, and the partner company takes it from there when the goods arrive.

2. Your Fulfillment Company Sorts Your Goods

Fulfillment companies receive inventory shipments in much the same way any warehouse or retail store accepts new inventory. Using the shipment details you provided, they check-in your stock by verifying quantities and inspecting for damage.

It’s standard for them to confirm receipt and communicate any discrepancies before proceeding—allowing you to work with your supplier or shipping company to be credited for damaged or lost goods.

Order fulfillment companies will sort and check-in your stock by verifying quantities and inspecting for damage.

Once received, your products are managed and organized within the fulfillment center through a tagging system—just like in any warehouse or brick-and-mortar store. There are different methods used for this task, and the type of system utilized is largely dependent on the partner company you choose. Many companies offer the ability to coordinate with your personal SKU system for use in their tagging and organization (but this often comes along with fees based on SKU quantities and bin requirements).

Some fulfillment centers—like Red Stag Fulfillment—specialize in advanced warehouse management system (WMS) features such as RFID tracking, video monitoring, and automation. These options are popular with merchants that sell high-value goods.

Did You Know?

ShipBob, a well-known order fulfillment company, reports a 99.95% accuracy rate when fulfilling client orders. More than 5,000 ecommerce businesses use the service, with 99.89% of reported orders shipping on time.

3. Inventory Is Stored by Your Fulfillment Company

With expert tagging and organization systems in place, your goods then move into storage.

As opposed to a traditional warehouse meant for static, long-term holding, a fulfillment center is designed for optimized logistics and fast turnover. Keeping a healthy amount of merchandise available must be balanced against storage fees that incur when your excess stock sits around taking up space. Experts recommend preventing your goods from being stored in a fulfillment center for longer than one month.

ShipBob’s warehouse shelves are lined with easy-access bins so products can be stored and picked efficiently. (Source: ShipBob)

Sellers should keep regular shipments coming in to ensure available stock is always sufficient to meet order demand. Data provided by your fulfillment partner can assist you in maintaining that balance. The growth of your company results in a more profitable partnership for them, so your fulfillment service provider is always happy to work with you in refining your processes.

Depending on the type of merchandise you sell, optional features like climate control and increased security measures can be added to your storage service to keep your goods in shape. Assess your specific needs and have them in mind when choosing which fulfillment company to use.

4. Customer Orders Are Routed to Your Fulfillment Company

Now that your inventory is safely delivered to, received by, and stored within your fulfillment center, it’s ready to process your customers’ purchases.

No matter which system you choose to accept and manage your orders, fulfillment companies go the distance to make connectivity simple. If you don’t have an order-receiving system in place, they can provide an online portal for manual order entry. Some fulfillment partners will even take care of this task for you, or offer customer service options to accept your orders via phone or email.

Here are some of the most common order-routing options.

Complete integration with your retail point-of-sale (POS) system, order management software, or ecommerce platform is the best way for your business to relay orders to a partner fulfillment company. This option automatically routes your orders to your fulfillment company’s internal system, allowing it to receive comprehensive order information—including product specifications, customer info, and shipping method—as soon as the order is placed.

Complete integration is common between most fulfillment companies and top ecommerce platforms, POS systems, and order management systems. Since integration increases the efficiency of their operations, most fulfillment companies heavily promote this capability and offer it at no additional cost.

When shopping for a fulfillment partner, look for compatibility with your existing order-receiving system.

If your fulfillment company doesn’t fully integrate with the system you use, you can send orders in bulk using a comma-separated value (CSV) spreadsheet.

This file type is a universal data format that most systems recognize. Virtually every spreadsheet program, POS system, ecommerce platform, and order management tool allows you to save your order data in a CSV file.

Most fulfillment companies have either a client portal to upload these files or an account representative who can take care of CSV entry for you. Depending on your sales volume, you may need to export order sheets multiple times per day, once per day, or even just a few times each week. The CSV file method requires more labor and attention than other streamlined options, but once the process is set up, it’s simple to perform.

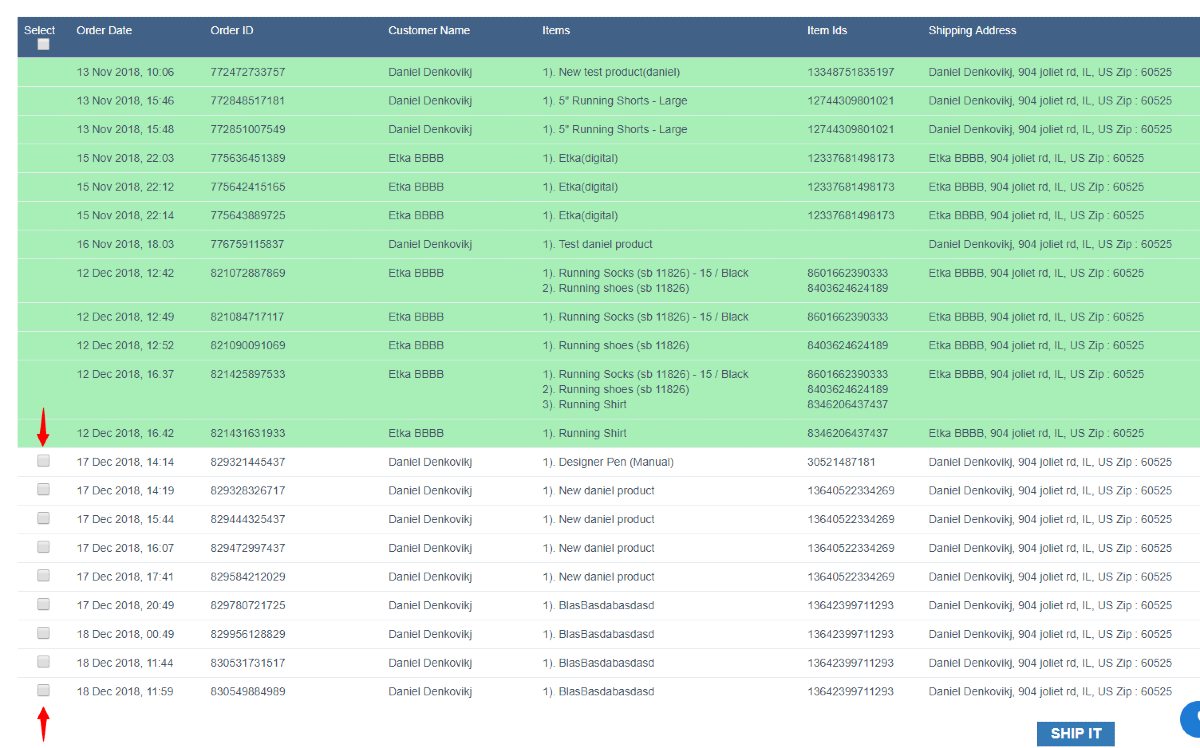

An order sheet submitted through ShipBob’s platform. (Source: ShipBob)

Most fulfillment centers’ online portals also have a feature that allows for manual order input.

It’s the least efficient method of transmitting order data to your partner company—each piece of order information is either manually typed or copied and pasted into the page, requiring lots of time and leaving your orders prone to error.

For sellers that prefer to keep their setup as simple as possible or maintain independence from technology, this rudimentary option comes in handy. Even for businesses using the other order-submission methods explained above, manual entry is often the best means of entering phone orders, shipping sample requests, or handling other special order needs.

5. Your Fulfillment Center Processes & Ships Your Orders

Once your partner company receives your orders, it will process them for shipment and get them on their way to your customers. This part of the operation is commonly called pick, pack, and ship. Here’s how each step works.

“Picking” describes the process of selecting and retrieving ordered items from stored inventory. Often your fulfillment center will keep a small amount of stock near its packing station for efficiency, and reserve a larger portion in storage to periodically pull from.

Fulfillment staff scans or checks the products they pick against your order information and then moves your items into the packing stage to prepare each shipment.

In packing, staff double-checks the accuracy of the picked items and packages them accordingly. If your goods require assembly, many fulfillment companies offer the option to add specialty labor to this step.

Fulfillment centers are equipped to offer a range of shipping boxes, mailers, and packing materials to ensure the safe delivery of your items. They can even help you develop customized packaging for a branded unboxing experience, or assemble several products into a packaged group (an option called kitting). In response to the rising popularity of curated subscription boxes, many fulfillment partners offer kitting services tailored to this format.

Order receipts, return labels, and any other inserts are then added in the packing phase, which all can be easily customized as well.

Once everything is properly packed, the fulfillment staff seals the boxes, weighs the orders, and labels them for shipment. If a specific shipping method or carrier was designated on the order, staff will route the package accordingly. In all other cases, the partner company will rate-shop to find the lowest rate and most reasonable delivery time for each order.

Rate-shopping helps cut your shipping costs while keeping customers happy with quick deliveries. Since fulfillment companies usually ship in great volume with all carriers, you’ll enjoy far lower rates than you’d get shipping packages on your own.

Depending on the size and weight of your goods, partnering with a fulfillment company that specializes in shipping heavier products may make the most economical sense for your business. Red Stag Fulfillment’s capabilities are geared toward larger, weightier parcels averaging 10 pounds or more, and it offers a 30-day risk-free trial to find out if their service is a good match.

Once shipped, your fulfillment company will update the order status to your ecommerce platform, POS, or order management system. You can even set up automatic email notifications that send shipping information to your customers, allowing them to receive confirmation and track the status of their delivery.

Did You Know?

- Fulfillment makes an impact—85% of consumers say they won’t shop with a brand again after a poor delivery experience.

- It pays to be transparent—60% of shoppers are more likely to complete a purchase if the estimated delivery date is visible in the shopping cart.

6. Your Fulfillment Center Processes Customer Returns

Upon arrival of the order, the fulfillment process is complete—unless your customer wants to return the goods they purchased. Fortunately, using fulfillment services makes this easy for you and your customers alike.

Most fulfillment centers receive and process returns as part of your basic service. By listing their address on any return information you publish or labels you send out, customers simply ship their unwanted goods directly to the fulfillment center where they are handled.

You define the requirements for items to be added back to inventory, sold on clearance, or discarded, and your fulfillment company’s staff handles returned merchandise accordingly. Reports you receive from them for each returned item can be used to issue refunds or credit back to your customers depending on your store’s return policy.

Some fulfillment companies charge restocking fees or returns-processing costs, so it’s important to know their pricing structure before partnering. If you sell goods with a high return rate—such as fashion apparel or electronics—be sure to consider this step of the cycle when shopping for fulfillment services.

Why Use a Fulfillment Company?

With an understanding of how order fulfillment companies work, you might be wondering if your business could benefit from fulfillment services.

While performing these tasks in-house makes sense for many small-scale sellers, 60% of ecommerce retailers choose to outsource some or all of their fulfillment needs to a third party, according to a widely reported DHL survey. Here are the top reasons why.

The fulfillment process is complex and demanding; it requires a significant amount of time, attention, and space to be performed effectively.

One of the greatest benefits of handing off fulfillment tasks to a third party is being able to redirect your time to areas where it may be better spent. Owners often find that the profitability increase they see from committing more attention to marketing, product sourcing, or development outweighs the cost of outsourcing fulfillment.

If your daily priority is handling orders to be packed and sent out the door, important tasks that actually help grow your business often take a back seat.

Fulfillment companies can easily scale services based on order volume, which is another major benefit to outsourcing this function.

Since they allocate space and staff across many accounts, you only pay for what your business actually uses. Then, when growth or seasonal fluctuations change your fulfillment needs, a flexible fulfillment partner can quickly allocate more resources to keep things running smoothly.

Performing your fulfillment operations in-house means adjusting labor and space capacity to handle shifts in order volume. This comes along with the increased workload of handling warehouse leases, payroll management, overhead expenses, and more. Then, when business naturally slows down, you can be left with an unwieldy excess of resources.

By letting a fulfillment company manage these details for you, your business can be ready for anything—making it a popular option with dynamic ventures like crowdfunding projects.

Partnering with a fulfillment company is like hiring a team of experts to do what they do best. Fulfilling orders is a complex process with lots of moving parts, and any oversight or inaccuracy can have a big impact on customer experience. By outsourcing it to specialists, accuracy and efficiency are guaranteed, and fulfillment success is supported by a laser-focused operation.

Red Stag Fulfillment’s highly specialized infrastructure and staff result in maximal accuracy and efficiency. (Source: Red Stag Fulfillment)

In addition to expertise, fulfillment partners offer cost benefits from their unique relationships with shipping and supply companies. Since they purchase packing supplies and shipping services in great volumes, they can negotiate far better deals than any small business could hope to get on their own. Most fulfillment companies pass these savings on to their clients to gain and secure their business.

When you run the numbers, the savings on shipping and packing materials alone often covers a large portion of your overall fulfillment costs.

Disadvantages of Using a Fulfillment Company

While there are many benefits to outsourced fulfillment, downsides exist as well—especially when partnering with less-than-reputable fulfillment companies. Here are some drawbacks to consider:

Order fulfillment is going to rack up a significant cost whether you choose to outsource it or perform it in-house. But, since there are no set industry standards for fulfillment charges, third-party companies structure their fees in a variety of different ways that can be confusing or even exorbitant.

While some fulfillment companies itemize each individual charge (such as per-hour receiving labor, storage space, packaging, and outbound shipping), many others charge a single ‘fulfillment fee’ that includes a mix of multiple different cost centers. This practice is becoming increasingly common and can make tracking your fulfillment expenses very difficult—especially for startups that don’t have a history of in-house fulfillment costs to compare.

There’s also the possibility that using a particular fulfillment center turns out to be more expensive than alternative options, which takes a bite out of your bottom line. Depending on the provider, terminating fulfillment service can be difficult and costly, incurring fees to break your contract, remove your inventory from storage, and relocate it to another center.

To avoid these drawbacks, we recommend going with a fulfillment partner that doesn’t require a contract and offers fully transparent pricing.

Outsourcing your fulfillment process means turning over a lot of control to a third party. In the event of problems like delayed shipments, stockouts, or problematic orders, this means that you are unable to intervene first-hand.

Or, even worse, it could lead to recurrent mistakes and errors (like late deliveries or swapped orders) that impact your customer experience. This can cause a high churn rate and invite dreaded negative reviews.

Many fulfillment centers focus heavily on communication with their clients, enabling them to return some of that control to the seller. Additionally, high-quality fulfillment partners will measure and publish their error or accuracy rate, giving you a real-time look into how many mistakes they make. Be sure to research these attributes and select a fulfillment partner that won’t compromise your control.

Performing fulfillment in-house enables you to connect with your customers in a way that fulfillment centers can’t replicate. Fulfillment partners typically focus on efficiency and either don’t allow or charge extra for any custom touches that slow down the process.

For example, it’s common practice for fulfillment companies to allow clients to use custom outer boxes that display their branding—but you’ll have to pay for the time it takes their packers to retrieve and use the extra boxes, in addition to storage for them (plus the cost of the boxes in the first place).

Outsourced fulfillment also makes it difficult (or impossible) to fulfill special customer requests, which can be a crucial touchpoint for generating loyalty.

Ultimately, third-party fulfillment is best for businesses that don’t need to make frequent changes or customizations.

While fulfillment companies take on most of the tasks involved in order fulfillment, only a very select few of them will reorder inventory from your suppliers. In most cases, that duty remains your responsibility.

But without first-hand knowledge of your stock levels, it can be tricky to place supplier orders at the right time—you have to rely on the fulfillment center’s quantity reports.

In the event that you’re unable to monitor your account on the fulfillment company’s portal—or if the posted quantities aren’t up to date—you could wind up with a stockout before you’ve re-ordered the product.

To avoid delayed orders and unhappy customers, go with a fulfillment provider that offers a user-friendly online platform. Also, be sure to check that it maintains a high accuracy rate and a good reputation among its clients.

Fulfillment Center Frequently Asked Questions (FAQs)

The main difference between logistics and distribution is that logistics relates to the planning and organization of how goods are moved, stored, and kept track of—while fulfillment describes the process of physically getting the goods to where they need to go.

When working with logistics, the primary concern is strategy surrounding the flow of goods from one point to another. This deals with inbound transportation, outbound transportation, handling, warehouse management, inventory management, and more.

While there may be some overlap between logistics and fulfillment, order fulfillment primarily focuses on preparing, packaging, and transporting goods to the end customer.

The main difference between fulfillment and dropshipping is who owns the inventory. In third-party fulfillment, the merchant owns the inventory and hires the fulfillment provider to store and ship it for them. In dropshipping, the fulfillment provider owns the inventory, and the merchant sells it on their behalf.

If you buy a drop-shipped product online, you’re visiting a website that was built and maintained by the seller, even though they don’t physically have any of the products listed. The seller forwards your order—along with the payment—to a third-party supplier who has the goods on hand. The supplier then fulfills the order by sending it out to the customer.

Conversely, sellers who use third-party order fulfillment already own the products they sell. After buying goods in bulk from their supplier, they have a large amount of the merchandise sent to the fulfillment center. Then, when orders come in, they are forwarded to the fulfillment company, which packs and sends them out to the customer.

Fulfillment companies are hyper-specialized operations that excel at efficiency, allowing them to ship large quantities of orders for a sizable network of clients every day.

They then charge each client for every order they send—along with storage fees, receiving fees, and more. The scale of these operations enables them to charge more money than they’re spending while still offering a reasonable cost. Because most retail businesses sell at a much smaller scale, they would rack up greater expenses doing the same tasks on their own.

The large volumes that fulfillment centers ship make them eligible for massive discounts from shipping companies, which creates an even greater profit margin

Bottom Line

Using services provided by a partner fulfillment company to manage inventory, process orders, and ship goods allows you to focus on growing your business. Outsourcing these functions provides a host of other benefits as well that can promote development and optimize your resources.

The fulfillment requirements of each seller are unique, and a vast number of different partners and services are available to choose from.

Knowing how your needs stack up against your fulfillment service options is crucial to finding the right match. Check out our recommended order fulfillment companies to learn more about how these services can work for your small business.