A minimum order quantity (MOQ) is a sales strategy used by wholesalers and other B2B suppliers in which they set a minimum number of products they will sell in a single order. For example, a clothing supplier may require that retailers purchase a minimum of 100 T-shirts per order, not allowing them to purchase any quantity lower than that.

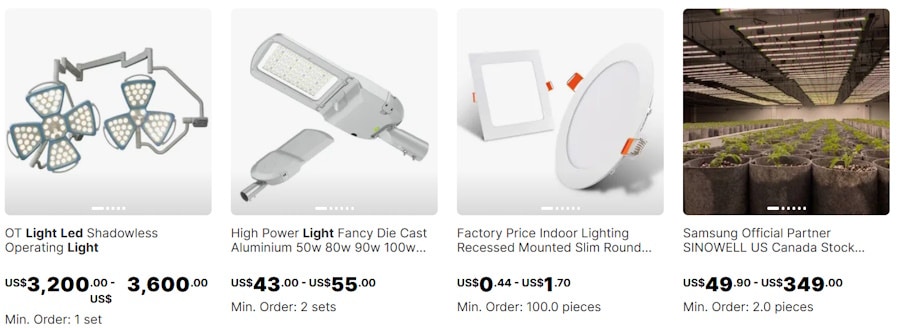

Some ecommerce sites list minimum order quantities for various products being sold

Why Do Suppliers Set Minimum Order Quantities?

Suppliers set minimum order quantities to ensure they make a profit on the goods they are selling. Whenever a supplier creates a product, they do so in mass. This mass production of a good incurs costs for materials, labor, storage, and shipping. From there, suppliers sell to retailers at below-market, wholesale prices. The problem is that this wholesale price leaves suppliers with per-unit margins that are not high enough to offset the associated costs.

To counteract this, suppliers set MOQs to sell enough products per order and make an acceptable profit. In other words, they take advantage of economies of scale.

Types of Minimum Order Quantities

Minimum order quantities are categorized as either simple or complex. Below are the key differences between the two.

Simple MOQs

Simple MOQs have only a single order requirement or criterion—typically a minimum quantity or a minimum spend.

Returning to the minimum order quantity example above, a simple MOQ set by a clothing supplier might require a retailer to buy T-shirts in batches of at least 100 units, or alternatively, to spend at least $1,000 per order.

Complex MOQs

Complex MOQs involve multiple order requirements or criteria based on calculations of cost and revenue for materials, logistics, labor, etc. To use the same T-shirt example above but with a supplier that sets a complex MOQ, a retailer may be required to purchase shirts in batches of 100, with at least 30 each of medium and large sizes, and at least 50 in the color blue.

Pros & Cons of MOQs for Retailers

While wholesalers and suppliers set minimum order quantities to reduce waste and maximize profit, the reality is that MOQs mean certain drawbacks for retailers. Here are some advantages and disadvantages of minimum order quantities for retailers in particular.

Pros of MOQs

- You’ll avoid stockouts: If you’re obligated to purchase a minimum number of items every time you order from a supplier, you can at least be assured that your stock levels will remain adequate for some time, and you won’t need to order new inventory very often.

- You’ll minimize repeating costs: Larger orders mean you’ll save on repeating purchase order costs such as shipping and admin expenses.

- You’ll pay a lower cost per unit: Purchasing in mass quantities typically means a lower unit cost for you—again, this is economy of scale at work. Assuming you can get all your inventory sold over time, this ultimately means greater profits for your business.

Cons of MOQs

- More expensive total costs per purchase: If you’re dealing with higher MOQs, you’ll have to pay greater purchasing costs every time you buy from a supplier, potentially impacting your cash flow. You may have to accept this at the beginning but can likely negotiate better deals later on as your relationship with your supplier develops.

- Increased pressure to sell ordered items: Your business might have its own projections of how many of each item can or will be sold to customers per month—but there’s no guarantee that this will align with the MOQs your supplier sets. In the worst-case scenario, you may end up with lots of spare inventory that you were obligated to purchase but cannot sell, incurring carrying costs.

Tips for Working With Suppliers That Use MOQs

Most suppliers use MOQs, so you will have to figure out ways to navigate your product sourcing so you don’t sacrifice your bottom line. Below are some tips you can use when you are working with suppliers that require MOQs.

Use Inventory & Customer Data to Optimize Ordering

Even if you can’t get your supplier to budge on their MOQ requirements, you can still optimize your inventory management to avoid over-buying on low-selling items and to determine which items to buy in large quantities. The right inventory management software will give you reporting and analytics about incoming and outgoing stock, best and worst sellers, item and batch tracking, product directories, vendor portals, purchase ordering tools, and more. This information can help you better understand what merchandise you should buy in mass and what items you shouldn’t.

Negotiate With Your Products in Mind

While adapting to a supplier’s MOQ can help you avoid stockouts, you can also negotiate with them to set a higher MOQ for best-selling items (they will likely agree, as it means a larger order from you). This ensures that you have lots of inventory for the items you know will sell well. You can also order heavier or custom items in larger quantities, minimizing higher repeating costs for these products.

Build Strong Relationships With Suppliers

Consistently meeting your supplier’s MOQ helps you build a stronger relationship with them over time. Once enough trust has been established, you may be able to negotiate and acquire certain benefits like free or discounted product shipping, merchandising tools and materials such as point-of-purchase displays for the supplier’s products in your store, and flexibility with MOQs for existing or new product lines.

Seek Higher MOQs for Evergreen Products

For products that you know will always sell in large amounts, look for higher MOQs—these will still be a sound purchase even if you need to pay a larger initial purchase cost because you know there is a solid demand. Economies of scale will help here again, ultimately netting you more profit even if you order very large quantities of these items. In the same vein, look for lower MOQs for seasonal goods that you know probably won’t sell very quickly or reliably.

Frequently Asked Questions (FAQs)

Read through the following sections to learn more about suppliers’ minimum order quantities and how to adapt to them as a retailer.

MOQ stands for minimum order quantity. It is the smallest amount of product that a supplier or wholesaler is willing to sell to a retailer in a single purchase order. Suppliers set MOQs in order to save as much as possible on production costs while maximizing profits.

MOQs will often be listed directly on the supplier’s product pages. If not, reaching out to the supplier via phone or email is your best bet at finding out their products MOQs. At the start of a business partnership, it’s unlikely that you’ll have much say over the MOQ your supplier sets. As the partnership becomes more established, it may become possible to negotiate better terms for yourself.

Retailers who need to adapt to working with suppliers that require MOQs can do so by managing their own inventory and sales as efficiently as possible and developing good working relationships over time with their suppliers to gain potential benefits.

Bottom Line

Whether your retail business is just starting out or has been around for a while, you’ll inevitably need to deal with suppliers who will require minimum order quantities. Though you may not be able to negotiate or get around these constraints (at least at first), you can still use the strategies in this article to adapt to these requirements, while continuing to minimize your own business costs and push your profits as high as they’ll go.