Properly using product codes such as SKUs and UPCs can help small businesses manage their inventory, track sales, provide strong customer service, and more.

SKU vs UPC: What Are They & When to Use Each

This article is part of a larger series on Retail Management.

An SKU (stock-keeping unit) and a UPC (universal product code) are both product identifiers that you’ll use in retail inventory management. Although similar, they have different characteristics (i.e., length and composition) and uses.

The primary difference between SKU and UPC is that an SKU is created internally for business-specific inventory tracking, while a UPC is created externally for broad supply chain compatibility. SKUs have varying lengths made up of both letters and numbers while UPCs always have 12 numbers and no letters.

Our SKU vs UPC guide takes a closer look at each type of identifier, including when and how to use each and best practices.

What Is an SKU?

An SKU features both numbers and letters to help retailers identify products and track inventory. As we mentioned above, SKUs are internal—meaning retailers create their own SKU systems and naming structures to make the identifiers as useful as possible for managing their specific inventory. They can be any length, although generally 8–12 characters, and are used to identify color, size, style, collection, product type, and more.

(Source: Lightspeed)

So, for example, an apparel retail business owner might create an SKU naming system that includes a letter at the front to indicate what type of clothing it is. They could use the following:

B = Bottom

D = Dress

A = Accessory

And then, taking it further, they could include identifying characters for sizing, color, and gender. So, maybe an SKU number could read T1BM0323 for a men’s small shirt in blue. The coding breaks down as follows:

1 = Small (using 0–4 scale for extra small through extra-large)

B = Blue

0323 = March 2023; the date the SKU was entered

This is just an example. You can create your SKU naming structure in a way that makes sense for your business’s internal processes. You might also add identifiers for product collections, vendors, and other information you’re interested in tracking.

Retail business owners can manually create SKU sequences or use point-of-sale (POS) software that creates them automatically. Lightspeed Retail is a popular cloud-based POS typically used by brick-and-mortar shops with high SKU counts as part of its robust inventory management feature set. Visit Lightspeed Retail.

When to Use an SKU Number

Retailers should use SKU numbers when they receive goods from suppliers. This will allow you to stay organized, track stock, and minimize data discrepancies and human error. Plus, a well-organized SKU numbering system can keep your warehouse and inventory storage areas easier to navigate.

And, while SKU numbers are great for retailers’ internal tracking processes, they are also customer-facing and friendly for shoppers because savvy online shoppers may search by SKU number to find the best purchase options. Plus, associates can more easily find products on the sales floor with a useful SKU numbering system, which is especially helpful when shoppers ask about availability.

Here are some examples of when you’d need to use an SKU number:

- Find out how many units you have on hand of a specific product or SKU

- Run price checks via SKU search when you’re unable to scan or use the barcode

- Monitor shrinkage by item

- Determine if an item is out of stock or if you have more in the store, warehouse, or elsewhere

- Create organization in your stockroom or warehouse

- Check receiving and ensure you’ve been supplied with the correct quantity of goods

- Pull sales reports by SKU number

- Check up on reordering points and restocking needs

- Identify which store or location the item is at or from

Learn more in our ultimate guide to SKU numbers.

What Is a UPC?

A UPC only features numbers and is always 12 digits long. UPCs are standardized, remaining the same no matter where, when, or how a product is offered for sale. They are purchased and licensed by product manufacturers so their products can be consistently tracked across the supply chain.

Generally, a UPC includes a company prefix (the first 6 to 10 digits), which identifies the brand owner—used particularly for larger manufacturers with many products; an item number assigned by the brand owner (the next 1 to 5 digits); and a final digit resulting from a formula involving the 11 previous digits.

(Source: Sticker Mule)

Because UPCs are universally used and recognized, they are regulated by an international nonprofit organization called the Global Standard Organization (GS1). The company that designed the product in question must purchase UPCs from GS1. You might also hear of UPCs referred to as a Global Trade Identification Number (GTIN)—they are the same.

In the news: In 2022, GS1 announced its Sunrise 2027 initiative, which will replace the traditional UPC with a two-dimensional, QR-code-style barcode. It will be able to store and convey more information, including recalls, sell-by dates, ingredients, sustainability data, and much more.

When to Use a UPC

You’ll need to use UPCs when manufacturing products or making your products available on the global retail supply chain. This includes listing your items on third-party marketplaces like Amazon.

To get a UPC, you’ll need to go to the GS1 website and determine how many UPCs (or barcodes) you need. You’ll need different UPCs for product variations such as color, size, style, and even packaging (i.e., plastic garment bag vs cardboard T-shirt tube).

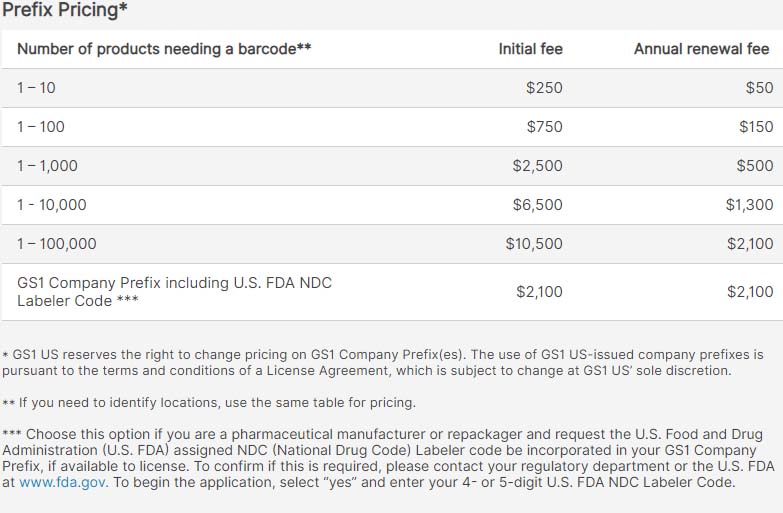

Once you know how many you need, you’ll need to consider which type of UPC you want to invest in. Smaller businesses can go for the GS1 US GTIN, whereas larger retailers with extensive or growing inventories may pay extra and apply for a GS1 Company Prefix, which enables them to get multiple barcodes at a time. GS1 recommends the latter if you have more than nine products. A GS1 US GTIN costs a one-time fee of $30, while the GS1 Company Prefix uses the following pricing structure:

(Source: GS1 US)

UPCs rarely change and should always be used when selling your products in the global supply chain.

How to Manage & Track SKUs & UPCs

A full-featured POS system will help you manage and track all your SKUs and UPCs in a centralized location, synced across all store locations and sales channels. POS systems can automate SKU and UPC tracking and use information to deliver notifications and analytics reports about your business.

While UPCs are more straightforward and give you less wiggle room, you’ll want to set up a naming convention for your SKUs that will work now and in the future. Consider business plans and, more importantly, your product expansion plans. Taking the time to properly set it up in the beginning will pay off in the long run.

Lightspeed POS is a robust solution with features to help manage all your inventory. It can handle up to 10,000 SKUs and product variants, bundles, and kits. You can add SKUs and UPCs manually or import them from an existing database. It’s our top-recommended retail POS for inventory management.

After your SKUs are entered into your POS or inventory platform, you need to create usable SKU numbers. In other words, you need to print them on labels so that customers and staff can refer to the SKUs and use them for the purposes mentioned above. Explore our list of the best barcode label printers to help you choose the right tools for your business. Or, learn how to create your own barcode labels with SKUs or UPCs (retailers will often use both SKUs and UPCs together in one product barcode label).

UPC vs SKU Best Practices

Using UPCs and SKUs is pretty straightforward, but following a few best practices will ensure you get the biggest inventory management bang for your buck from these product identifiers.

- Only buy and license your UPCs from GS1; there are scam sellers that provide fake or discontinued UPCs.

- Plan carefully and consider future product needs before purchasing a GS1 prefix plan. For example, if you purchase the plan for up to 100 products but end up needing more, you’ll have to purchase a separate plan with a different prefix.

- Consider what product attributes you want to track via your SKUs and devise a deliberate numbering system; random SKUs will do you no good.

- Don’t over-complicate your SKUs; they should be easily understood by all your employees, so short and simple is better.

- Don’t use SKUs created for a product by the manufacturer or other entity; SKUs should be specific to your business. Also, don’t reuse SKUs from a discontinued product.

- Use characters in your SKU that can easily be read/identified by your employees and your computers.

- As we mentioned above, use POS, inventory management, or other software to automate and effectively manage your UPC/SKU process.

- Review your SKUs/UPCs so they accurately reflect your inventory levels and product assortment.

Bottom Line

In an SKU vs UPC comparison, the biggest difference is that SKUs are internal (for inventory management) and UPCs are external (for supply chain tracking). Each has its own uses, and you may even be obligated to use a UPC in some contexts, but both work together to help you easily track, find, and identify inventory.

Managing your SKU and UPC processes with a POS like Lightspeed gives you every tool you need to maintain your inventory and sales floor efficiently. It provides streamlined, user-friendly inventory management and reporting tools with the capacity to handle lots of items. Visit Lightspeed to learn more.