Creating a new, unique product is exciting for retailers and a great opportunity for growth. However, manufacturing can be daunting, especially if you don’t know where to start. This article will look at how you can manufacture new products for your business, from ideation to bulk production for your store.

Step 1: Develop a Product Concept

To begin your manufacturing process, you will first need to develop a product concept. This means thinking of a new product idea that is both original and appealing to your target market. Anything less will result in products consumers can obtain elsewhere or don’t want.

The four most significant components you should consider at this stage in product development are need, market, ability, and cost. Consider the following:

Don’t want to invest in product development? Consider selling private label products, where you customize an already successful item with your branding or other small adjustments.

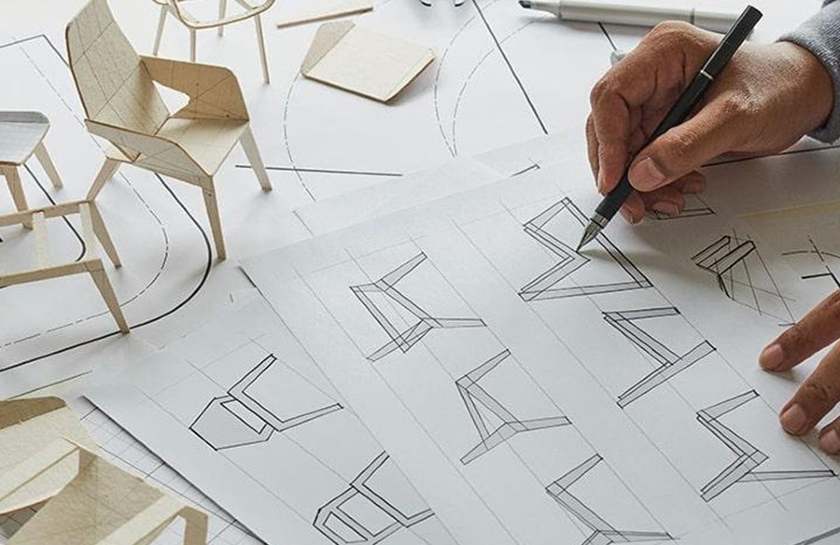

Step 2: Create a Prototype

Once you have developed a product concept that is financially viable and fills a need for your target market, it is time to develop a prototype. A prototype is a preliminary product model from which you and your manufacturers will develop your final product. Your prototype can be physical or digital; either way, it needs to be a clear enough rendering of your vision that your manufacturers can use it as the basis for the goods they make for you.

Some manufacturers have a product development process where you can produce and develop prototypes alongside your manufacturer. This process can be expensive, however, so you can also utilize tools like:

- Drawings

- Reference photos

- Written instructions

- 3D modeling software

- Freelance product designers (Fiverr, Upwork, TopTal, Dribbble)

At this point in the development of your product, you might want to enlist the help of a product development consultant, especially if this is your first time going through the manufacturing process. A product development consultant can help you research, develop, launch, and maintain your product, providing industry insights, money-saving tips, and experience in your product development process.

While you can look to product development consulting firms to find and hire a resource, most SMBs do not need this level of support (or expense). Instead, consider your own network, and try to enlist the help of someone who has been through the manufacturing process before and would be able to provide guidance. Mentorship is one of the most powerful tools in cultivating success for your business and products, so don’t hesitate to look to your friends and associates to get the insights you need.

This is also the time that you should take legal steps so that no one can take your idea and sell your product for themselves. The agreements and legal issues you should consider to protect your product are:

Non-disclosure Agreement

This is an agreement you can sign between yourself and anyone you work with in the manufacturing process that prohibits the disclosure of information about your product and its production.

Non-compete Agreement

A non-compete agreement is typically signed between you and your manufacturer or anyone else working closely with you in product development and creation. It states that participating parties will not take your idea to create their own business/product that competes with you and your product.

Patent

Under US law, you can obtain a patent for your product within one year of it going for sale. A patent excludes others from making or selling an invention or design, giving the patent owner exclusive rights to manufacture and sell their invention or idea. However, patents will not prevent international manufacturers from stealing your designs as US laws do not bind them.

For more on obtaining a patent in the US, check out the United States Patent and Trademark Office.

Step 3: Find Manufacturers

Once your prototype is ready, it is time to find a manufacturer to produce your product so you can start selling.

Finding the right manufacturer can make or break your product, so be sure to do your research to find the best match.

A cut sheet, also known as manufacturer specifications, is a document that outlines all the details the manufacturer will need to create your products. You should have your cut sheet prepared as you shop manufacturers so they can understand the scope of your project and assess whether they have the tools to accomplish it.

The information you should include on your cut sheet is

- General information—business name, product name, description of product

- A picture or prototype of the product for reference

- Product dimensions and weight

- Product care information

- Packaging and logistics

- Timeline—when you will need the product and subsequent turnover times

- Materials—type of material, description of the material, color, quantity, supplier

- Notes—any notes needed to help the manufacturing company create the product

We will look below at some of the resources you can use to find a manufacturer—there are thousands to choose from. The first thing you will need to do is determine what you need your manufacturer to do. Consider the following variables and ask any manufacturers you are considering about them:

- Logistics: How quickly can they produce and ship products? What carrier(s) do they use? How much do they charge for shipping and handling? What packaging do they use?

- Quantity: Are there minimum order quantities (MOQs)? Can the operation scale? Do they offer custom order sizes?

- Price: How does price scale with quantity? Are there less expensive options?

- Reliability: Look for a supplier with good reviews, full licensing, and a reliable production line. You should also check the Better Business Bureau and any other company reviews to ensure there haven’t been any complaints filed.

- Capability: Before proceeding with a manufacturer, you want to check whether the product you need is within their manufacturing capabilities.

- Labor Practices and Safety: Labor laws and practices vary by country and manufacturer. A good way to vet a manufacturer is to see whether it is certified by the Fair Labor Association or has received any other labor and safety accreditations.

- Environmental Impact: Another factor you may want to consider is your manufacturer’s environment ethic. Many manufacturers pledge to lower emissions and reduce waste or participate in other environmental efforts, which will often be noted on their websites. You can also use the Thomasnet.com search engine to find environmentally friendly suppliers.

When choosing a manufacturer, consider whether you want to work with a domestic or an overseas supplier. It is often cheaper to source your labor overseas, especially in Asian countries like China, India, and Taiwan, because labor costs are lower. Even if you do choose to work with an overseas supplier, I recommend having a local resource to act as a more reliable backup.

In general, there are fewer domestic manufacturer options, and their labor and material costs will be higher. With domestic manufacturing, however, you do not have to overcome a language barrier, and shipping is typically faster and cheaper.

While manufacturing costs will be your biggest expense, also consider the costs of freighting your products from the manufacturer to your store or warehouse (which we’ll cover a bit more below). In other words, even though an overseas manufacturer may be more affordable than a domestic manufacturer, be sure to factor in freight costs to get a true comparison. Learn more about budgeting a retail business.

Once you set your priorities and know what you need from your manufacturer, you can start using different resources to find the best ones. Below, we will look at different places where you can find the right manufacturers for your business.

Step 4: Obtain Quotes from Multiple Sources

Once you have found a few suppliers, vetted them for reliability, and ensured they could work with your logistical, cost, and quantity requirements, it is time to start getting quotes. Quotes are price estimates based on your needs that manufacturers send to you before you commit to a purchase.

In our interview with Calloway Cook, he said, “I’d recommend getting quotes from 10 or more suppliers because prices can vary drastically.” This strategy will give you a good idea of what pricing is reasonable for your product and allow you to choose the best price.

To obtain a quote, you must reach out to suppliers, typically via email. When entering a working relationship, the last thing you want to do is bombard your manufacturer with emails, so include all the relevant information upfront. That includes:

- Needs: Be clear about what you need from the supplier (i.e., I would like to potentially work with you to produce a new furniture product for my store—a Tempur-Pedic foldable lawn chair—and would like to request a quote).

- Details: Provide as much detail as possible about your desired product. Ideally, you will include images of your prototype or 3D renderings, material information, and any other relevant info about your product (i.e., I would like to use Tempur-Pedic cushioning with plastic covers, painted metal legs, etc.).

- Numbers: The last thing you need to include for getting a quote is numbers—typically how much of the product you need. You should also include if you need to rush production or any other numerical considerations that might impact price (i.e., I will need 300 lawn chairs in four months).

Step 5: Order Samples

Based on your quotes, you should then narrow down your top manufacturers, typically based on price at this stage. I would recommend choosing at least two viable options so you can compare their finished products and make a final decision based on quality.

With your top contenders chosen, you can then reach out and order samples. Samples are test products manufactured in single or very small quantities for retailers to assess prior to entering full production. A sample is key for ensuring that your final product is what you want it to be and can act as a point of development with your manufacturer to create the final product.

Ordering samples is typically pretty easy. All you have to do is request a sample via email from your manufacturer and provide your prototype and any instructions; the manufacturer will use that as the basis for a sample product.

Your sample product will be much more expensive than your final goods—four to five times more. Do not fear, however, as once you enter final production, your unit price will go down.

Step 6: Set Your Terms

Once you have settled on a manufacturer and tested and finalized your final sample, you should expect to enter into contract negotiations with your supplier. At this stage, the main topics you should discuss and possibly negotiate are your payment terms, order quantities, and logistics.

Step 7: Manufacture Your Product

Now that all the pieces are in place, it is time for you to wait. At this point in the process, there is little to do other than communicate with your supplier and wait for your products to arrive.

What’s next? When you get your products, it’s time to start selling. Check out these resources to get started.

- How to Start a Retail Business

- How to Start an Online Store

- How to Market a New Product

- Best Ecommerce Platforms

Product Manufacturing Frequently Asked Questions (FAQs)

Click through the questions below to get answers to some of your most frequently asked product manufacturing questions.

Manufacturing costs vary depending on the materials you use, how many products you need, where you produce your product, shipping costs, and many other factors. You can estimate your manufacturing with the equation,

Total manufacturing cost = materials costs + labor costs + overhead costs

The range for manufacturing costs can be anywhere from $100 to over $100,000.

Product manufacturing is all the processes involved in the creation of a product, using labor, machines, computers, and raw materials.

To manufacture a product, you can follow these seven steps

- Step 1: Develop a Product Concept

- Step 2: Create a Prototype

- Step 3: Find Manufacturers

- Step 4: Obtain Quotes From Multiple Suppliers

- Step 5: Order Samples

- Step 6: Set Your Terms

- Step 7: Manufacture Your Product

Bottom Line

Manufacturing a new product takes a lot of time and energy. Once you have completed the process, however, you will have a new working relationship with a manufacturer and a new product that is all your own. With our guide, you are ready to start manufacturing your own products and seeing your ideas come to life on your shelves.