Radio-frequency identification (RFID) is technology that uses electromagnetic fields to identify, track, and transmit data—such as the specific item number, batch number, or item production date—via a tag that is attached to an item. The reader device displays all of this information, which is useful for inventory management tasks such as tracking stock quantities and movement and even preventing theft.

In this article, we’ll look at how RFID technology works, its pros and cons, and the typical costs of using the technology for inventory management.

How RFID Technology Works

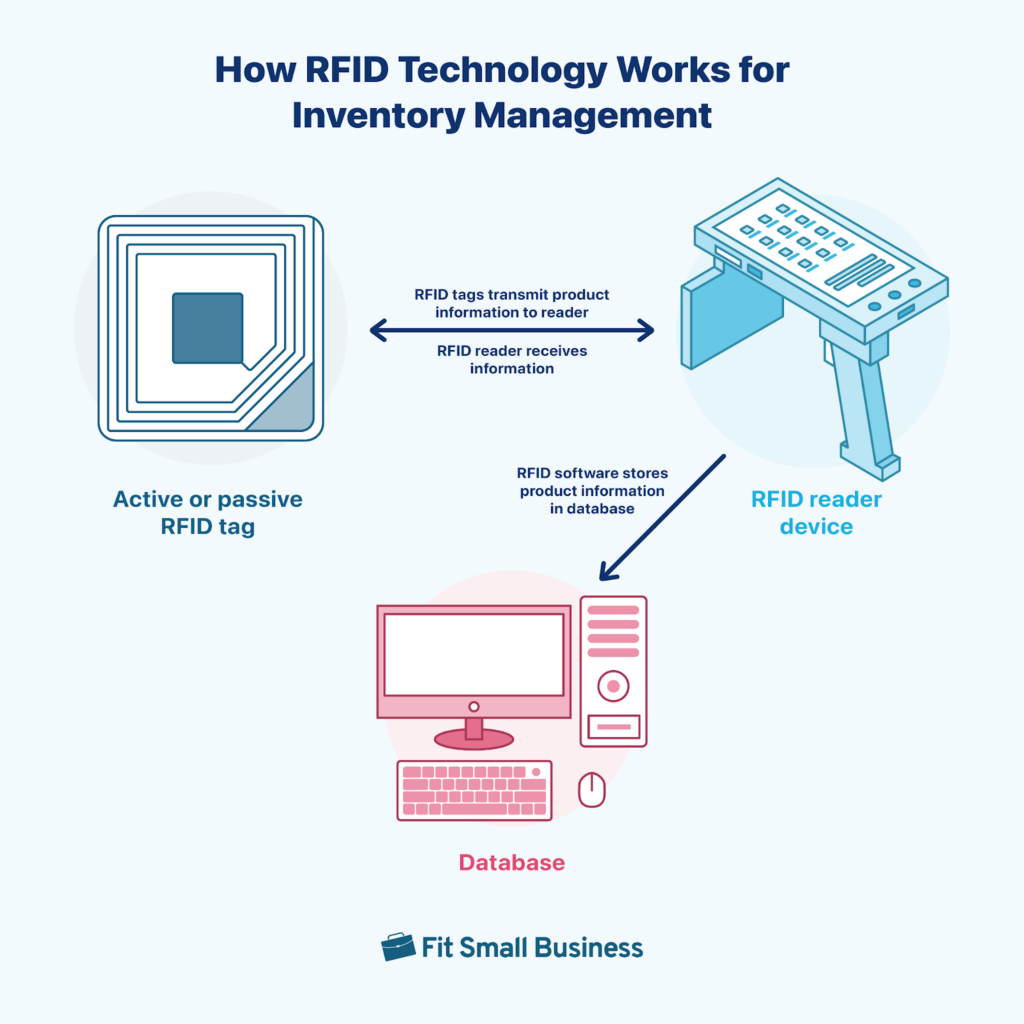

An RFID inventory management system has two components: an electromagnetic tag and a reader device, both of which feed information into your database.

Whenever new stock comes into a store and is logged into the inventory management system, store staff attach an RFID tag to each item (or to a group of items, such as a pallet). Each tag contains digital data (typically inventory details and quantities) about the product.

The tags will likely already have been pre-configured by the manufacturer, but you may be able to reprogram them using RFID middleware RFID middleware is a type of software that connects RFID hardware to business applications. so that the product information appears in your database exactly as you want it to.

RFID tags can be passive or active (we’ll explore the differences further below). When a store employee carrying the reader device triggers it to transmit an electromagnetic signal or pulse, any passive RFID tags attached to nearby products will detect that signal and return a signal of their own, transmitting information about those products to the reader. Some RFID readers do not transmit a signal or pulse on their own and instead receive signals from active RFID tags.

By using the reader, employees can keep track of a huge number of products in real time, even if these products are moving around inside a factory, warehouse, or store branch. If programmed as such, reader devices can also sound alarms upon detecting a tag. For example, an RFID reader can be placed in the doorway of a retail store or warehouse, and detect a tagged item that passes through the threshold.

RFID Technology Use Cases

RFID technology has several possible uses—for retailers, most of these fall under the umbrella of inventory management. RFID technology allows you to see inventory quantities and movements, from groups or pallets, down to individual items. This makes the technology useful for:

- Supply chain management

- Granular quantity tracking and inventory counts

- Theft and loss prevention

- Managing multiple locations or warehouses

- End-of-day reconciliation of sales records

- Ecommerce and multichannel businesses

- Vehicle and delivery tracking

Types of RFID Tags

There are two main types of RFID tags: passive and active tags.

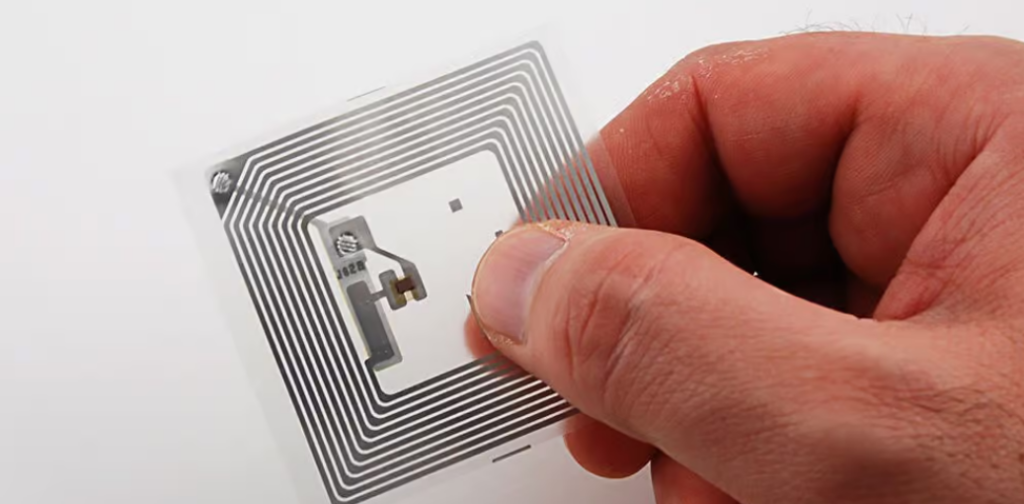

- Passive RFID tag: A small tag containing a microchip that stores product information and an antenna for transmitting and receiving signals from an RFID reader. Passive tags do not contain batteries and are powered by the electromagnetic signal that comes from the RFID reader.

With passive tags, you’ll never need to worry about depleting and replacing batteries. Passive tags are also cheaper to obtain. However, the reader will need to be very close to a passive tag in order to detect it; for smaller or low-frequency tags, the distance may be as short as one meter.

Passive tags are useful for basic inventory management and tracking, access control systems like door keycards, and waste management.

Passive RFID tags do not need an internal battery but have a very short detection range. (Source: Rayming PCB & Assembly)

- Active RFID tag: Contains a battery and transmits its own signal regularly without relying on an initial signal from the reader. Because of this, a reader can detect active tags at a much greater distance than passive tags—up to hundreds of meters, in some cases.

This makes active tags a better choice for tracking inventory movement across large spaces such as warehouses and keeping tabs on delivery vehicles and their cargo. Because of this advantage, active tags are much more expensive than passive tags.

Active RFID tags have an internal battery and a much longer detection range. They often have a more rugged construction than passive tags. (Source: Atlas RFID Store)

RFID vs Barcode Label Inventory Management

Generally, using barcode labels is more cost-effective than RFID technology. However, barcode labels can store only limited information and must be scanned within a very short range. RFID for inventory management has advantages in terms of speed, functionality, and accuracy, albeit being more expensive.

Here are some key differences in how they work:

- Barcode labels are typically able to store general information such as stock-keeping unit (SKU) numbers, universal product codes (UPC), and manufacturer information. RFID tags can store more complex information including expiry dates and product maintenance details.

- A barcode scanner needs to be within a very short range (just a few inches) and in the line of sight of the barcode sticker on the item. An RFID reader, however, can detect information from an RFID tag without a direct line of sight, even if the tag is obscured by certain objects or materials, such as packaging.

- Barcodes can only be scanned or read one at a time while multiple RFID tags can be detected by a reader simultaneously. This makes RFID technology a better choice if the main priority is the speed of scanning or if it’s vital to make fast and regular inventory counts.

- RFID tags are more expensive than barcode labels. Attaching RFID tags to every item in a large inventory will be a much more significant expense than doing the same thing with barcodes.

Pros & Cons of RFID Inventory Management

| Pros | Cons |

|---|---|

| Improved security and loss prevention | More expensive than other inventory management systems |

| Real-time, item-level inventory tracking | Active RFID tags require regular battery replacement |

| Fast and flexible stock counts | Possibility of data flooding |

Pros

- Improved security and loss prevention: Using RFID to track inventory at an item level is useful not only for stock management but also for security. If an RFID-tagged item is detected passing through an area where it should not be—for example, past the entrance of a store—this can alert store staff that an attempted theft may be underway.

- Real-time, item-level inventory tracking: If tagged items are moved from one location to another, RFID technology will let you know that this is taking place. This can be anything from shifting products from one section of a store branch to another to keeping track of when products leave the building to be shipped out to customers. With a fully set-up RFID system, this all happens automatically, with no need for manual tracking or intervention by users.

- Fast and flexible stock counts: Inventory counts are quick and efficient with RFID technology because the readers can detect multiple tags at the same time, and the tags are detectable even if they are covered by certain physical barriers such as packaging or even walls. In contrast, when counting inventory via barcode, you would need to scan each item manually from close range.

Cons

- More expensive than other inventory management systems: RFID tags are more expensive than barcode labels, especially if you choose to use active tags.

- Active RFID tags require regular battery replacement: If you go with active RFID tags, you’ll need to regularly replace the batteries (or replace the tags entirely). Failure to do so means that the tags will stop working, which may grind your entire inventory management system to a halt.

- Possibility of data flooding: Data flooding occurs with a large amount of useless data in the system. An RFID system detects and notes each movement of inventory, even if it is not significant or useful for inventory management or business purposes. One example is a customer or staff moving a tagged item between shelves in the same store, which has no impact on inventory management or sales.

Should I Start Using an RFID Inventory System?

An RFID inventory management system is not necessary if you’re just starting a small or new retail business or if you have a small inventory. As a small business, you’re not only working with a tight budget (which would get eaten up quickly by a bunch of active RFID tags), but your operation is likely not complex enough to require anything more than barcodes for inventory management—at least at the onset.

An RFID system is useful if you have a lot of fast-moving inventory, need heavy multi-location management (such as keeping track of stock transfer and separate inventory levels for multiple warehouses or store branches), or are an ecommerce- or delivery-focused shop. In these cases, the real-time tracking capabilities you’d get from RFID technology are more likely to be a good investment.

Costs of an RFID Inventory Management System

The cost of a complete RFID inventory management system varies widely, mainly because of the large price difference between passive and active tags. If you intend to purchase a large number of tags, the price difference becomes even more dramatic.

Passive RFID tags will cost you about 15 cents each, while active tags will cost you at least $25 each. More advanced active tags with features like protective housing and long-lasting batteries may run you up to at least $100 each.

An RFID reader will cost $500–$2,000 depending on the type of frequency it emits and the inclusion of accessories such as antennae and cables.

Frequently Asked Questions (FAQs)

Click through the sections below to learn more about what RFID inventory management is, its advantages, and its costs

This refers to using radio-frequency identification technology (in the form of tags and scanners) to count inventory as well as track and manage its movement.

Advantages include more options for security and loss prevention and efficient and fast stock counting and inventory tracking. Disadvantages include expense and maintenance requirements—in particular, replacing the batteries of active RFID tags.

Passive RFID tags cost about 15 cents each, while active tags cost at least $25 each. An RFID reader device costs from $500 to $2,000.

Bottom Line

RFID technology is an advanced tool for managing your inventory, with advantages and disadvantages. While it’s not necessary if you’re running a small business without a large inventory, it’s still an option to keep in mind for when your business expands and you begin to need more robust inventory management tools.