According to the Brewer’s Association, there are over 9,500 breweries in the US, with 549 new ones opening and 319 closing in 2022. If you love creating and sharing your own beers and are prepared to operate within the number of laws that regulate alcoholic beverage productions, starting a brewery can be very rewarding. It costs between $250,000 and $2.5 million to start a brewery, and most brewers start turning regular profits after about three years.

We cover how to open a brewery in 10 primary steps, with a deep look at branding and the legal requirements of this highly regulated industry. Note that these steps may not be taken sequentially; you may start working on your licensing even before you finalize a budget, for example. These steps cover how to start a microbrewery as well as a larger operation.

Before you start, do your research: Brewers agree that the more you know both about brewing and about business, the smoother time you’ll have starting a brewery. They recommend working in the industry, crafting your own beers, and shadowing a professional brewer before taking the plunge yourself.

Step 1: Determine Your Niche

Before you get into the deep work of starting your brewery, ask yourself: Do you want a place where you can show off your beers personally to an appreciative group or are you looking to have your label distributed regionally? And what are you doing that makes you stand out from the competition? Give deep thought to the kind of brewery you want—and what your area will support.

Type of Brewery

There are two major types of breweries: those that sell directly to customers, and others that manufacture beers for distribution to bars, restaurants, and retailers. Those two types can be further broken down into six major market segments based on their sales location and how many barrels of beer they produce annually:

- Microbreweries: Sell more than 75% of their beer off-site and produce less than 15,000 barrels (bbl) per year. A nanobrewery is an even smaller microbrewery, one that produces less than 2,000 bbl annually.

- Brewpubs: A brewpub offers food alongside beer, and sells more than 25% of its beer on-site.

- Taproom brewery: Taprooms do not serve food and sell more than 25% of their beers on-site.

- Contract brewing company: These hire other small businesses to produce some or all of their beer.

- Regional craft brewery: These can have worldwide recognition but produce between 15,000 and 6 million barrels a year.

- Alternating proprietor brewery: This is where two or more brewers share brewing equipment. Usually, one is the host and rents the space and equipment to the tenant brewer. This could be a good way to make a little extra money while working up the demand for your product.

Brewpubs are the fastest-growing segment for independent breweries and the model that most consumers think of when they think of a brewery.

What is a beer barrel (bbl)? Breweries measure the size of their business in barrels, abbreviated as “bbl.” One bbl is the equivalent of 31 gallons of beer. You’ll also see brewing equipment categorized by bbl.

Determine Your Brand

With over 9,000 breweries in the US alone, you need a way to stand out. Start with determining your target audience. In general, millennials are the biggest craft beer demographic, so start there. Next, think about your story. What’s driving you to create your beers? How do they do what other beers don’t? A great story goes a long way in websites, social media, and other advertisements.

Next, consider your logo, name, and label. It doesn’t matter how great your brew is if you don’t catch the eye of the consumer. Make it clear, clean, and reflective of your story. Then, trademark it to protect it.

Related:

- Tips for Naming Your Business (+ Free Name Generator)

- Best Sites for Logo Design

- How to Find a Niche Market

Step 2: Build Your Budget

In addition to the location, which can cost up to a million dollars by itself for rent/mortgage and renovations, you need to consider equipment and supplies, many of which are consumables. Manufacturing breweries have bigger expenses for location and equipment, while brewpubs need to consider everything required for a restaurant as well.

We’ve made extensive (but by no means complete) lists to get you started, along with estimated costs you’ll need to account for.

Once you figure all of these costs, finalize your budget by adding contingency funds. You should have enough money on hand to cover your fixed costs (like rent and utilities) and payroll for three to six months. It will take several weeks to see money from sales begin to enter your bank account. These contingency funds will ensure you keep your operation running smoothly until your sales start rolling in.

Expected Income

How much you make is directly dependent on how much you produce and sell. The average markup for beer is as much as 300%. One rule of thumb is to price at least four times the expected cost of production. Not all of that markup is profit, though. Most breweries see a profit margin of 20% to 25%. This is a lot less than that 300% markup, but a lot more than the 5% profit margin most restaurants see.

Despite the high markup, with expenses, it can take three to five years to turn a profit on your brewery. After that, the average annual salary of a brewery owner runs $50,000 to $88,000.

Step 3: Create a Business Plan

A business plan covers the basics of how to start a beer company. We cover the steps in-depth in our article on creating a business plan. However, in general, you will need:

- An executive summary that gives the basics of the plan in a few clear paragraphs

- A mission statement and business objectives: How your brewery fills a niche and serves the community, along with your concrete goals

- Competitive analysis: Who your competitors are and how you are similar and different

- Budget

- Location

- Products and services

- Marketing strategy

- Sales forecasts

- Milestones

- Management and employee structure

- Financial data and analysis: Forecasting income and expenses for the next three years

When creating the business plan, remember that much will depend on outside factors, so try to give yourself some wiggle room for unexpected events.

Step 4: Find Your Location

First, you’ll want to be sure the area you’re considering is zoned for brewery and alcohol sales. Then, make sure the rent and utilities are within your budget and consider how much the refit costs will be. Sometimes, a more affordable second choice is the best choice. In most cases, breweries tend to be outside of densely populated areas. Breweries simply need a lot of space for equipment, an enormous amount of water, plenty of room to dispose of spent grains, and neighbors that are too nearby can complain about the smell.

It’s not that breweries smell bad, but not everyone appreciates the aroma of fermenting yeasts and sugars wafting into their apartment or office space. So you’re likely looking mostly at suburban and rural locations. Warehouse districts in former industrial neighborhoods of large cities are also rich with potential. Consider Angel City Brewery in Los Angeles, which is housed in a historic warehouse in the Los Angeles Arts district.

Look for spaces that have previously been used for manufacturing a product. Most simple retail and restaurant spaces simply don’t have enough water or electrical infrastructure to support a brewery, and upgrading these services can be costly. Brewing equipment is also very heavy; an empty brew tank can weigh more than 1,000 pounds. You need a space that can handle the weight.

A brewery location depends greatly on whether you are attracting customers to your space, like with a taproom, or brewing for businesses. (Source: Pixabay)

Wherever your brewery is located, you’ll need a space that has:

- Ample space: Do you need a bar for the taproom, a kitchen for your brewpub, or loading docks?

- Floor drains for the brewery equipment

- High ceilings and ample space make it easier to work with the equipment, especially for manufacturing breweries.

- Ample Utilities: Be sure you have sufficient electricity, gas, water, and sewer services.

Brewery equipment provider ICC-NW suggests these minimum utility requirements for your brewing equipment:

-

- Electrical 20 – 35 kWh/beer barrel (bbl)

- Natural Gas 2.0 – 3.7 therms/bbl

- Water 6 – 8 BBL’s water/bbl beer produced

- Refrigeration 10 – 20 BTU chiller capacity/bbl yearly capacity

- Direct Fired Brew Kettle 25,000 30,000 BTU/bbl Cast Wort

If all those numbers make your eyes cross, call an electrician and a brewery equipment technician to come look at your space. Most brewery equipment providers are happy to send a technician or sales rep to see if a location can support their equipment; the sooner you settle on a location, the sooner they make a big sale.

Brewery Size

Size matters when considering how to start a brewery business. Too small and you hinder expansion; too large, and you’re paying for unused space. ICC-NW recommends the following:

- Complete Brewery: 0.5–1 sq. ft./bbl of yearly capacity

- Sacked Malt Storage: 0.15–0.25 sq. ft./bbl of yearly capacity

If you have a taproom or brewpub, you need to add space for the bar, restaurant, and kitchen as well.

Step 5: Secure Funding

If you lack the funds, there are plenty of options available. Most people know about startup business loans and lines of credit, but did you know there are grants available, too? You can also seek out investors or business partners.

Your business plan goes a long way in helping you secure bank loans, grants, or partners. Consider creating a pitch deck or slide show with the most important information to make an easy presentation. Find more information on what you need to secure a small business loan in our guide.

Another popular alternative is crowdfunding, where people contribute in exchange for rewards or equity to your investors. There’s a special crowdfunding site for breweries: CrowdBrewed, which caters to beer enthusiasts. It also offers learning opportunities and a place to connect with other brewers and beer lovers.

You should also look into a business credit card, which gives you some quick flexible funding for smaller expenses as well as a place to pay for subscriptions like brewery management software or a POS system.

Step 6: Get Permits, Licenses, and Insurance

The alcohol industry is highly regulated, so you’ll want to be sure you get all the needed permits, licenses, and insurance. If you own a taproom or brewpub, you may need even more. Check with the Tax and Trade Bureau for Alcohol and Tobacco, your local Alcoholic Beverage Control (ABC) Board, and the Brewers Association State Laws for what’s required in your area. Below is a list to get you started:

- Incorporation: Bars and businesses that make consumable products take on a lot of liability, so you need to incorporate your business to separate your business assets from personal ones. Most breweries incorporate as LLCs. A business attorney can advise you on the best decision for your brewery. These are the most common. Follow the links for more information on each.

- Employer identification number (EIN)

- State tax ID

- A Federal Brewer’s Permit

- A Brewer’s bond

- Liquor license

- Food and beverage license

- Retailers license

- Sign permit

- Certificate of occupancy

- Registration with the Alcohol and Tobacco Tax and Trade Bureau

- Liquor liability insurance

- Business income insurance: While optional, it can protect you if you need to shut down temporarily.

Depending on your location and your plans, you may also need permits for pool tables, live music, or permits for placing your dumpster. In addition to the food safety inspections performed by your local health department, breweries must register with the Food and Drug Administration and pass an impromptu inspection. They will check that you are meeting federally mandated standards for sanitation and employee hygiene called the Good Manufacturing Practices for Craft Brewers (GMPCB).

Step 7: Purchase Equipment & Source Suppliers

Under your budget, you’ll have listed the types of equipment and pricing—but how much should you buy?

This depends on the size of your brewery, available floor space, and how you intend to sell. However, the general guideline is buy a little more than you expect to use. The Asian Beer network recommends at least a 10-hectoliter (HL) tank and a mix of 5HL and 10HL fermentation vessels.

“This means for your biggest selling beers you will get around 1800–1900 of sellable beer per batch (less for a heavily hopped IPA). You can still have half brews of 500L to some dedicated tanks for niche beers that you know will not sell in big quantity,” they say on their website.

Some brewers have found that they can cut the costs of equipping their brewery by as much as half if they design their own system and source used parts. Check message boards and networks for brewers selling used equipment.

The quality of your supplies will impact the quality of your product. (Source: Pixabay)

When sourcing suppliers for your ingredients and consumables, be sure you find businesses that you can trust. Start by asking around for recommendations, and do your own homework. Checking with the Better Business Bureau and online reviews is a good start. When interviewing, ask about minimum order amounts, payment policies, quality assurance processes, and general business practices.

Software is an important part of any modern business. When evaluating software, look at user and professional reviews, then ask for a demo or check out the free trial before committing. Some companies have a free but limited version of their software. This may serve you well in the beginning, but keep in mind that as you grow, you may need to purchase a subscription or change software.

We’ve not evaluated brewery software, but untapped.com recommends Ollie. We looked briefly into it and found it’s a very complete system for tracking manufacturing tasks and sales. It also has an average 4 out of 5 user review rating on multiple sites.

Step 8: Develop a Distribution Plan

Distribution is key for breweries, it is how you get your beer in front of customers. As with most things related to alcoholic products, your distribution options vary widely according to state laws. The laws that regulate the sale and distribution of alcoholic beverages like beer are called franchise laws, and you’ll need to contact your local liquor control board—or an experienced lawyer—to learn what is permitted in your area.

Some states allow you to self-distribute a set number of barrels to local retailers, while others only permit direct-to-consumer keg and package sales. In some states, breweries that want to distribute their beers can only do so through a licensed distributor. The Brewers Association maintains an online database of state laws that can give you a good idea of what to expect.

Distributors take between 20% and 40% of your price. For that sum, distributors do more than warehouse and transport your product. They build relationships with retailers and consumers, so it’s important to your business to find one that’s well-respected in the community too.

When sourcing a licensed distributor, start by asking local brewers for recommendations. The Brewers Association also has a list of distributors. You need to find one that matches your plan: Are you planning on staying local or branching nationwide? Then, make sure you understand their policies and get a good feel for their dedication to the art of craft beer.

- Ask how long they’ve been in business, especially in your area of interest.

- Review their portfolio. Consider the volume of products they’re selling, the location, and the types of beer they distribute.

- Tour the facility. Verify capacity and ability to effectively store and transport your products.

- Ask about their competition and how they stand out.

- Learn about their representatives. These are the people who will be selling your beer in the region or across the nation. Also, ask how a representative is replaced if they fall ill or take leave.

- Get a list of references or key accounts that you can call.

Step 9: Hire & Train Staff

The average United States brewery employs about 11 people at any given time. Some of the common positions you need to fill are:

- Head brewer

- Assistant brewer (can be an apprentice)

- Engineer (to look after the equipment)

- Microbiologist or chemist (analyze the microbes)

- General manager

- Sales

- Customer service

- Bookkeeper

Naturally, if you have a bar or restaurant, you’ll need waitstaff, host, barbacks, and kitchen staff.

Beertenders, also called a beer sommelier or a cicerone, are a special breed of bartenders for breweries. They cannot only recommend a beer, but also beer/food pairings. They should have a good knowledge of your beers and of the beer industry overall, as well as a winning personality so that they create a positive experience for your consumers.

Training Your Staff

When hiring staff for your brewery, consider hands-on experience as well as formal education. Many brewers (perhaps even you) are self-taught or had a few courses, and many people are looking for the chance to learn. Consider hosting apprenticeships or internship programs as you build your staff. Other staff members, such as your microbiologist or engineer, will need certifications or a formal college degree.

Many breweries apprentice staff to train them in their methods. (Source: Pixabay)

This is a highly regulated industry, however, so you’ll want to be sure your training includes not only how to brew great beer and use the equipment, including software, but also meets federal and state regulations for food safety, alcohol serving, and even sexual harassment prevention training.

Also, take care to follow local laws when hiring interns or apprentices. It is generally safest to pay all interns and apprentices at least minimum wage for their work to ensure you stay within the bounds of the law.

Step 10: Market Your Brews

Marketing a craft beer starts with your name and labels. Craft brews need to stand out, and that starts with your label. Start with your brand, and then name beers in fun ways that reflect it.

Some of the most popular labels play off brewing terms, like “Hoppy Ending” or “Pathological Lager.” Next, design an eye-catching label to go with it. If you have graphic design skills you can do it yourself with a design app like Canva. If design is not your strong suit, hire a freelance graphic designer from a site like Fiverr.

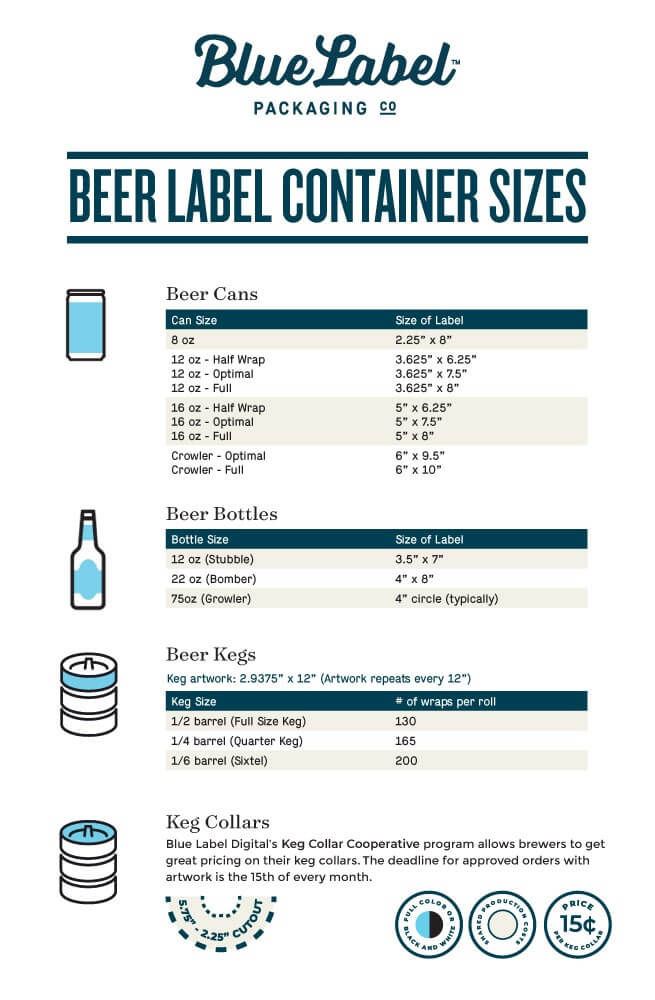

This guide shows you the label size you need based on your product type. (source: Blue Label Packaging)

Various states have different laws regarding the information that must be included on beer labels. Check with the local liquor control board for the correct information for the markets you plan to sell to. If you work with a label printing service (which you should—they save a lot of time and money) they can also usually provide you with the correct labeling information for your product.

According to the Brewer’s Association, millennials are the biggest target customer for breweries, so go where they are on social media. Also, be active in your community; according to Stellar Partnerships, 82% of millennials want businesses to make a positive social impact, 79% will recommend a company based on their social involvement, and 70% are more loyal to brands they believe benefit society.

You should also consider platforms like Untapped to gamify your customer relationships. Untappd is a community of beer drinkers nine million strong. They collect badges made by bars and breweries, such as for trying a special brew or attending a special event. Learn more about Untappd and how to make an Untappd badge. If they operate in your market, setting up an account with third-party alcohol sales and delivery platform Drizly is another great way to reach new customers.

Beer tasting, called flights, is a good way to bring in customers and show off your new brews. Offering mixed six-packs or refillable growlers (glass, ceramic, or stainless steel bottles for taking draft beer home), is a good way to encourage repeat customers. Retail items or swag like T-shirts or beer cozies that promote your company are also good investments, especially if they are fun.

Websites cannot be underestimated. This should not only show off your beers but also tell your story. Millennials and GenZ respond better when they connect with the people and values behind your brand, so don’t just show off your great products, but also your location, people, and overall vibe. If you distribute and serve your beers at third-party locations, make sure to include a beer locator page where customers can find your beers in the wild.

The website for Tommyknocker Brewery + Pub in Colorado highlights their bright, signature cans, and tells customers where to find their beers. (Source: Tommyknocker’s Brewery + Pub)

Related:

Beers are synonymous with events from sporting events to concerts. Consider renting booth space at outdoor festivals in your area to start getting your beer in front of customers. Your local Chamber of Commerce or tourism board can typically supply you with a list of events that would be good fits. You can also throw your own events in your taproom or brewery to draw crowds to your location. Consider booking popular local bands, or hosting some kind of contest to get free media and get customers energized about your brews.

In many locations, there are restrictions on how alcohol-based business can market their products. In many places, you cannot offer free beer any larger than a tasting portion. Check with your local liquor control board to stay on the right side of the law.

Opening Your Brewery

You’ve put in the planning, done the hard work, and gotten the word out. The only thing left is to open for business! Be sure to involve the press and any beer influencers in your area. An Untappd badge is also a great draw for enthusiasts who might not make the trip otherwise.

Grand openings are exciting, but if you have a taproom or brewpub, a soft opening, with family and friends, is a good way to work out the kinks and give your staff practice before the big, high-pressure event.

Pros & Cons of Opening a Brewery

If you like beer and are the creative type who still has a head for business, then starting your own brewery can be both satisfying and profitable. However, there’s a huge startup cost and strong competition—plus, the act of brewing itself is meticulous and full of dull work like cleaning.

| PROS | CONS |

|---|---|

| Creative work with a splash of chemical engineering | Highly competitive market |

| High profit margins | Requires a lot of cleaning |

| Formal brewing education not required | Data tracking and methodology are vital—can get dull |

| Brewers say it’s a meditative process, while running the business is an extroverted activity | You never drink beer the same way again |

| Joy of sharing your creation with an appreciative audience | Fermentation is a 24/7 activity |

Frequently Asked Questions (FAQs)

These are some of the most common questions we hear from prospective brewery owners.

Most breweries average a profit margin of about 20%, which is much higher than the standard for restaurants (which floats closer to 5%). And brewery businesses are currently growing in the US. According to the Brewers Association, retail dollar sales of craft beer in 2022 increased to $28.4 billion (5%), and make up 24.6% of the $115 billion US beer market. If you run your brewery efficiently, you can expect to earn a profit in the first three years and pay yourself from $50,000 to $88,000 a year.

Check the section on budget for a more complete list, but in general, you need:

- Manufacturing location, perhaps in conjunction with a bar or small restaurant

- Brewing equipment

- Ingredients

- Licenses and permits

- Software for managing people, money, and inventory

- Great employees

- Strong marketing

You’ll also need the ability to manage details (like routine administrative and cleaning), work well with people, have some salesmanship, and a good (pardon the pun) head for beer.

Nanobreweries do better as taprooms or brewpubs, so if you want to be profitable as a microbrewery business, that’s the best route. If your plan is solely distribution-based, your path to profitability will be more difficult.

The best business structure for your brewery will depend on your brewery type. Small breweries may be fine simply incorporating as an LLC, while larger breweries may be better suited to a corporation. There is a lot of liability when you’re producing a consumable product, especially when that product is a controlled substance like alcohol. So definitely consult a business attorney to ensure you get the best business structure for your brewery type.

Bottom Line

Opening a brewery is about making great beer. But it’s also about arranging distribution plans, monitoring day to day cleaning and administrative tasks, and securing the correct permits and licenses. Following our 10-step plan will get you going on the right foot. Starting your brewery can take several months—and up to a year and a half—but those moments when someone sips your latest creation and grins with appreciation make it all worthwhile.