Inventory control is the process of continuously monitoring and adjusting the quantity of product you are stocking to keep costs as low as possible while maximizing customer satisfaction and store profits.

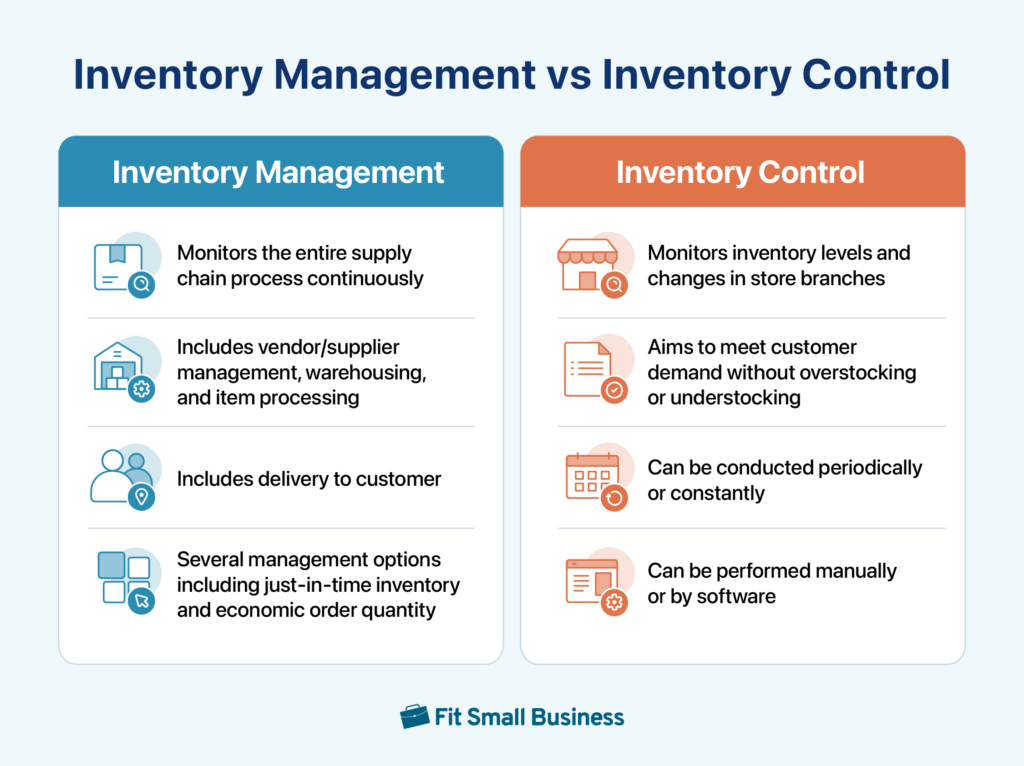

Though the principles of inventory control overlap with those of inventory management, the two are distinct:

- Inventory control is concerned with ensuring that there is enough product on hand in store branches, warehouses, and company storage locations to meet customer demand while avoiding overstocking. Inventory is counted regularly and frequently—every day, if necessary.

- Inventory management is concerned with the overarching supply chain process, including purchasing stock from suppliers and getting products into the hands of customers. It involves maintaining business relationships with suppliers and buyers, optimizing purchase ordering, and more.

Why Is Inventory Control Important?

Inventory control allows businesses to maximize revenue, minimize cost and waste, and get the greatest possible returns on inventory investment. Proper inventory control means you keep enough products in your store that all customers who want to buy will be able to do so, but not so many products that you end up with a ton of unsold inventory.

Businesses that do not practice inventory control (or perform it poorly) end up understocked or overstocked. The former would result in unrealized profits and annoyed customers, while the latter means that the business is spending too much on purchasing. In both cases, the business is not being run as efficiently as possible.

How Inventory Control Can Improve Your Business

Good inventory control benefits your business in ways that go beyond just stock management. In general, it makes your business run more smoothly by making things easier on your staff, reducing customer pain points, saving on business costs, and letting you convert resources into results more efficiently.

Here are some of the beneficial ripple effects of consistent inventory control:

Real-time Insight Into On-hand Stock

Thorough inventory control involves frequent stock counts. The best stock counts happen in real time, conducted by inventory management software that is purpose-built for this.

Real-time item tracking lets you know how much of a product you are selling and how much remains in your storage. You’ll be able to tell whether you have enough stock to meet the expected daily demand. This is especially useful if you’re running a multichannel store and need to ensure that you have enough overall inventory to supply all your sales channels.

Minimized Costs

One of the most immediately apparent benefits of good inventory control is reduced business costs. Avoiding excessive stock means that you won’t have to pay costs related to inventory: holding or storage costs, insurance, security, utilities, and labor, to name a few. The additional liquidity you’ll get from these cost savings can then be used for other, more productive purposes.

If you choose to use a perpetual inventory control method (which we’ll cover in the section below), then you’ll also be generating real-time reports on your inventory and sales. This data will provide more opportunities to optimize your processes and save on costs.

Reduced Manual Labor & Errors

A purpose-built software system will perform inventory counts and track movements continuously and with greater precision than a person could achieve consistently.

Staying on top of inventory control with the right tools and software will free up your staff members for other tasks—like ensuring that your customers get the best experience possible—while also minimizing the negative consequences of inventory count errors.

Improved Customer Satisfaction

If a business fails to track, move, or manage its inventory appropriately, this will result in stock being unavailable. This could mean a best-selling or high-value item being out of stock when a customer is itching to buy one, or a customer being unable to purchase a product from your online store because the inventory for that was allotted to somewhere else.

In either case, the buyer ends up disappointed and leaves your physical or online store—with a good chance of never returning. Maintaining good inventory control at all times lets you avoid this nightmare scenario and helps with customer retention.

Workflow Optimization

Workflow optimization is another benefit of inventory control that ties into all the other points listed above. The insights you get from proper inventory control—namely, the knowledge of how much inventory you need, how often, and where it needs to be—are invaluable for optimizing your workflow.

With these insights, you and your staff members will learn the optimal frequency and quantities for purchase orders, as well as when and where to transfer stock between locations. This will lead to further possible optimizations for staffing, business hours, supplier relationships, and decisions on brand expansion.

Types of Inventory Control Systems

There are two types of inventory control: periodic and perpetual—though many businesses take a combination approach.

Periodic Inventory Control

A periodic inventory control system involves doing inventory counts at specific times, like at the beginning and end of a certain period such as every month or year. At the chosen times, the company will conduct an inventory count to determine how much stock has been sold and how much remains. This also allows the company to determine other information such as the cost of goods sold and labor and material costs.

A simple example of periodic inventory control would be a small business closing down for a few days every quarter in order to manually count every product it sold and how many remain in its inventory. This information helps management make decisions on suppliers, purchase ordering, and multi-location management (if applicable).

Periodic inventory control isn’t always the best option (perpetual inventory control, detailed below, is often a better choice), but it may be the most realistic option for a business that is small and has few employees, a small inventory, and no inventory management software at the moment. If you’re just starting out with your retail business and have few resources, periodic inventory control might be enough in the meantime.

Perpetual Inventory Control

Perpetual inventory control involves keeping track of all inventory changes (additions, deductions, transfers) in real time. This requires a good point-of-sale (POS) system or dedicated inventory management software. Because inventory control is happening in real time, there is no need to designate specific time periods to assess inventory—which means there is also no need to close down your store to perform these tasks.

An example of perpetual inventory control is an established business with multiple locations or sales channels using an advanced inventory management system. Every time a sale is completed either in a physical store or via the brand’s ecommerce site, the software will immediately log the sale and the corresponding change in inventory. When the overall inventory count passes below a certain threshold, the software will notify staff members that it’s time to send another purchase order to suppliers. The system will also generate reports on demand, providing information on sales, inventory, and costs.

It’s important to note that periodic and perpetual inventory control are not mutually exclusive. Businesses may use a point of sale or dedicated inventory management system to track stock in real time, while also performing manual counts (such as cycle counts) periodically. A combination approach can help ensure that your inventory software remains accurate; any discrepancies can point to issues such as inventory shrinkage, errors on the part of suppliers or your own staff, and more.

Learn more: Perpetual vs Periodic Inventory Systems

Inventory Control Techniques

Here are a few techniques you can implement to optimize inventory control for your business. These techniques will allow you to keep track of what kind of inventory you’re holding, how much you’re selling, which items are being moved and where, and when and how to reorder from suppliers.

Manual Spreadsheets

The most basic way to control inventory is to log all product types, quantities, and changes on spreadsheets. Your employees will need to open and edit the spreadsheets every time a sale is completed, which is time-consuming and can easily lead to errors if something is forgotten or logged incorrectly.

Manually updating spreadsheets isn’t the most efficient way to perform inventory control, but it can be an option for a very lean small business that isn’t carrying a lot of stock.

Inventory Management Software

Inventory management software—whether part of a larger POS system or a purpose-built inventory management system—is the most efficient and comprehensive way to control your inventory.

The best software options perform perpetual inventory control, automatically logging all sales and inventory changes in real time. The software will be able to differentiate sales and inventory updates from different sales channels such as in-person vs ecommerce, track different item variants such as colors and sizes, generate reports, notify you of low stock numbers, and provide templates (or even full automation) for purchase ordering from suppliers.

Read more:

- Best Inventory Management Software for SMBs

- Best Free Inventory Management Software

- Best POS Inventory Systems

Item Tracking

Besides spreadsheets or software, you’ll need other tools to help you keep track of inventory.

The best way to keep track of individual items and have the ability to scan and count each of them is via using barcode labels or radio frequency identification (RFID) tags. Both options allow you to quickly scan individual items and get product information and quick inventory counts. In the case of RFID-tagged items, you’ll be able to track these as they move around within a warehouse or store branch, and (depending on the type and strength of the RFID tag) even monitor products as they get shipped out to ecommerce customers.

Another option is stock-keeping units (SKUs), which are codes made up of letters and numbers, designed to identify items and track inventory. SKU numbers can also help you keep an eye on product variants, such as color and size for clothing. You can create these codes manually, or have your software do it.

Frequently Asked Questions (FAQ)

Click through the sections below to learn more about inventory control, benefits and techniques, and common challenges.

Inventory control is a periodic or continuous process of keeping track of product levels, movements, and distribution in various store branches or storage locations. The goal is to ensure adequate inventory levels to meet customer demand without overstocking.

With good inventory control, a business can reduce staff workload and errors, save money, optimize work processes such as purchase ordering, and improve customer satisfaction.

Inventory control techniques or options include manual product tracking via spreadsheets, using dedicated inventory management software, and monitoring individual product information and movement via barcodes, RFID technology, or SKU numbers.

Challenges include a lack of transparency with inventory levels, overstocking or understocking, and murky or absent demand forecasting. A good inventory management software will address all of these by counting inventory in real time and generating reports with useful information.

Bottom Line

Inventory control is a basic but crucial process that you need to be doing—ideally continuously—to keep your stock at optimal levels for maximizing both profits and customer satisfaction. Whether you do it manually or automate it via software, you’ll need to stay on top of it to keep your buyers happy and your brand going strong.