Just in time (JIT) inventory is when retailers have the exact amount of supplies they need to meet demand on time, every time. The goal of JIT inventory is to have the minimum amount of inventory on hand, helping reduce costs and improve efficiency.

This inventory management strategy was made famous by Toyota in the 1970s: the car manufacturer had tight inventory control and worked closely with raw materials suppliers to ensure it always had just the right amount of materials to meet production needs—no more, no less.

How Does JIT Inventory Work?

Unlike other inventory management methods where you might stock up on goods to prepare in advance for future sales, JIT aims to align inventory levels closely with real-time demand. Here’s how it works:

- Understanding Demand: Effective Just In Time inventory management relies on a thorough understanding of customers’ current and upcoming demand. The better you can predict how much of a product you’ll sell and when, the more efficiently you can manage your inventory.

- Establishing Reorder Points: Most retailers use an inventory management software that lets them set reorder points for JIT. These are triggers that tell you when it’s time to order more stock based on your expected demand. The goal is to reorder just enough to ensure you don’t run out of stock before the new order arrives.

- Supply Chain Management: JIT requires having a strong supply chain—especially reliable suppliers. You’ll need to find and maintain relationships with suppliers who can deliver goods quickly and accurately once your reorder points are hit. Communication and sufficient bandwidth are also crucial, as well as efficient logistics.

- Continuous Monitoring and Adjustment: Lastly, JIT isn’t a set-it-and-forget-it method. It requires continuous monitoring and adjustment to ensure the system is running smoothly and tuned to current demand conditions. Using point-of-sale (POS) system data and inventory management software, you can track sales trends, update reorder points, and customize your alerts.

Pros & Cons of Just in Time Inventory

| PROS | CONS |

|---|---|

| More cash flow | Susceptible to supply chain disruptions |

| Decreases expired or wasted inventory | Little room for error; requires excellent organization and reliable suppliers |

| Lower inventory holding costs | Not environmentally friendly |

| Higher operational efficiency | Heavy reliance on accurate demand forecasting |

| Easier to pivot product assortment | Potential for missed sales |

| Less susceptible to theft | Higher per-unit costs |

Advantages of JIT Inventory

JIT inventory management has a number of benefits, including the following:

More Available Capital

Often, one of a small business retailer’s biggest assets is inventory. After all, it’s the crux of your business—without it, you have nothing to sell. However, when you have too much capital tied up in inventory, you’re limited in what you can do with those assets. You may need cash to fund a second store opening, build a new online store, or invest in product development. Plus, you use less cash buying stock that will become unsellable.

Less Wasted Inventory

Because you rely on lower levels of safety stock with JIT inventory management, you’re less susceptible to aging, expired, obsolete, and wasted inventory. This dead stock, or unsellable merchandise, is costly and wasteful. Many retailers resort to using discounts and promotional methods to clear out excess stock—reducing profit margins and incurring extra marketing costs.

Some estimates say dead stock costs retailers $50 billion per year. With the JIT method, you have fewer items on hand and prevent overproduction, so your inventory doesn’t have a chance to age or expire. Plus, because you create products in smaller batches, it’s easier and less costly to deal with manufacturing defects.

Lower Inventory Holding Costs

Less stock requires less space, which leads to reduced infrastructure needs, lower storage costs, and better-organized warehouse layouts.

In 2023, it costs an average of $8.22 per square foot to run a warehouse. The fewer square feet you have, the more affordable your warehousing expenses become. With JIT inventory management, you don’t have a lot of inventory to store, so you don’t need a large warehouse space. In some cases, you may not even need a warehouse at all.

Agility to Launch New Products & Change Your Offerings

Since the JIT inventory model relies on short production cycles, it’s easier to bring new product ideas to market. This also makes it easier for you to adjust to emerging trends or sudden changes in demand by switching up the products you sell. Some retailers even use the made-to-order model, so they don’t manufacture a new product until someone has purchased one.

It’s important to note that this may impact production for your other products. Some suppliers can keep up with both, while others may have to pause to have the capacity to manufacture your new products.

Local Sourcing Opportunities

Depending on where you’re located and the availability of supplies in your area, the Just In Time inventory method often presents an opportunity to source materials locally. When your suppliers are nearby, shipping is typically faster and much more affordable.

JIT can also foster closer relationships with suppliers, making them more like valued business partners rather than just vendors. With as many as 70% of consumers choosing to shop and support local, this is also an excellent opportunity for branding and marketing.

Reduced Theft

Internal theft alone has become a bigger priority in the last year for nearly half of retail businesses. You can reduce retail theft through the JIT method because you have fewer assets on hand to steal.

Here are some resources for other methods fighting theft and shrink:

- Effective Retail Loss Prevention Tips for Small Businesses

- Inventory Shrinkage: Definition, Causes & How to Prevent It

Challenges With Just In Time Inventory

While the Just In Time inventory strategy provides plenty of benefits, it also has a number of downsides. Keep these potential challenges in mind when assessing whether the JIT method is right for your small retail business:

Susceptibility to Disruptions

There’s a reason why it’s called “safety” stock—having extra inventory on hand gives you a security net for unexpected disruptions to your supply chain. These snags could include things like natural disasters, labor strikes, or equipment breakdowns. Moreover, freight and last-mile delivery are frequently delayed with little to no explanation at all. Similarly, unexpected spikes in demand can also put your business in a bind.

When using the JIT inventory method, you’re far more susceptible to disruptions like these, which could result in stockouts, dissatisfied customers, and lost revenue.

Little Room for Error

The JIT method also leaves little room for error. If you accidentally order the wrong amount or there’s a manufacturing defect, you don’t have a stock reserve to lean on while waiting for things to get back to normal. You need to have strong forecasting processes because inaccurate forecasts could lead to significant errors.

Reliance on Suppliers

JIT inventory control puts a lot of trust and onus on your retail suppliers. This can be uncomfortable and risky, especially for entrepreneurs used to doing everything themselves. That’s why it’s important to carefully vet and select the best wholesale suppliers for your business.

Ask about their ability to keep up with JIT and if other clients use this inventory management method. Also ask about price fluctuations, raw materials availability, and contingency plans for unforeseen circumstances.

Here are more resources to help you find suppliers and manage your relationships with them:

- How to Find a Wholesaler for Your Retail Business

- The Ultimate Guide to Product Sourcing

- The Ultimate Guide to Restaurant Food Suppliers

Environmental Impact

As sustainability becomes a more pressing global issue, businesses also have to be mindful of their environmental impact.

The JIT method isn’t the most sustainable inventory management style—it requires lots of shipping and packaging, both of which have significant negative impacts on the environment.

Organizational Demand

Because you have little room for error with the JIT method, you need to be extremely organized to mitigate those errors. You need advanced inventory control in place, and it’s important for everyone on the team to follow the same processes and guidelines. While automation and inventory management software will certainly help, they’re not foolproof.

Stress & Workload

With all of the pressures listed above, the JIT method puts a lot of stress on retail business owners and employees. It’s an agile way to do business, so it requires not only efficient workflows but also error-free work. Using this model, it can be challenging to stay on top of inventory needs in addition to everything else.

Profit Risk

When you order smaller quantities from suppliers, you typically pay a higher per-unit price, which cuts into your profit margin. This is often the case when it comes to JIT inventory management.

Plus, because you need product more quickly, JIT often involves working with local suppliers. While this may be more affordable in some cases, it also limits your ability to price compare and find the most affordable options.

Missed Sales

When you use the Just In Time inventory method, you’re more susceptible to stockouts, a costly problem in the retail world. Stockouts lead to not only missed sales but also a poor customer experience, which could have an immeasurable negative impact for years to come when you consider potential repeat purchases and word-of-mouth marketing.

Do you need an inventory management system? We evaluated the best free inventory management software for small businesses.

Who Should Use Just in Time Inventory?

Some retail industries and verticals are better suited for the JIT method than others. These niches may benefit from JIT inventory:

- Fashion and apparel: You may have heard of the term “fast fashion” before. It’s essentially the rapid and affordable production of apparel products so businesses can capitalize on trends. This aligns with JIT’s minimal inventory approach. Some sustainable and handmade brands also use the “made to order” model, which also suits JIT’s on-demand production style.

- Food and drink: Because food and beverages have shorter shelf lives, you don’t want to hold on to them for too long. As such, you may consider the JIT method to avoid spoiling and expired products.

- Print on demand: Print-on-demand businesses rely on the JIT method by nature. When a customer places an order, only then is a design printed on the item they purchased. T-shirts and art make great print-on-demand options. Note these products typically offer smaller profit margins.

- Cosmetics, beauty, and personal care: Similar to food and drink, many of these types of products have an expiration date, making them good candidates for JIT inventory management.

- Florists: If you sell living flowers such as bouquets, you may look into using the JIT method. These products have a short shelf life and are seasonal, so low inventory levels are usually beneficial.

Questions to Ask Before Transitioning to JIT Inventory

Transitioning to a Just in Time (JIT) inventory management system can significantly impact your retail operations. Before making this strategic shift, it’s important to conduct a thorough assessment to ensure JIT aligns with your business model and operational capabilities.

Here are some questions and areas of your business to consider:

- Demand Forecasting Accuracy

- Looking back at previous sales, how accurate are your current demand forecasting methods?

- Do you have the necessary tools and data to predict customer demand effectively?

- Supply Chain Reliability

- How reliable are your suppliers in terms of delivery speed and accuracy?

- Do your suppliers have experience with JIT inventory systems?

- Do you frequently encounter delays or errors with the logistics side of your supply chain?

- Operational Flexibility

- How quickly can your operations adapt to fluctuating demand?

- Do you have the necessary systems in place to manage real-time inventory adjustments?

- Technology Infrastructure

- Do you have the technological infrastructure to support a JIT system, such as real-time inventory tracking and automated reorder points?

- Is your POS system and/or ecommerce platform capable of providing real-time sales data to aid in demand forecasting?

- Finances

- Have you analyzed the financial implications of switching to a JIT system, including potential cost savings and impact on cash flow?

- Are you prepared for possible higher per-unit costs due to smaller order quantities?

- Organizational Preparedness

- Is your warehouse layout and storage system optimized enough to meet the organizational needs of JIT inventory?

- Is your team prepared for the change in workflow and increased organizational demands of a JIT system?

- Local Sourcing Opportunities

- Are there local suppliers available who can meet your JIT needs, reducing shipping times and costs?

- Long-term Vision

- How does JIT inventory management align with your long-term business goals and growth plans?

Companies That Use Just in Time Inventory

Here are some examples of companies that use the JIT inventory method.

Apple

One well-cited example of the JIT method is Apple. Back when the company still sold the iPod, it adopted the JIT inventory method to optimize production. It outsourced many of its production needs to places with more affordable manufacturing and ended up cutting the production cycle from 90 days to just 90 hours.

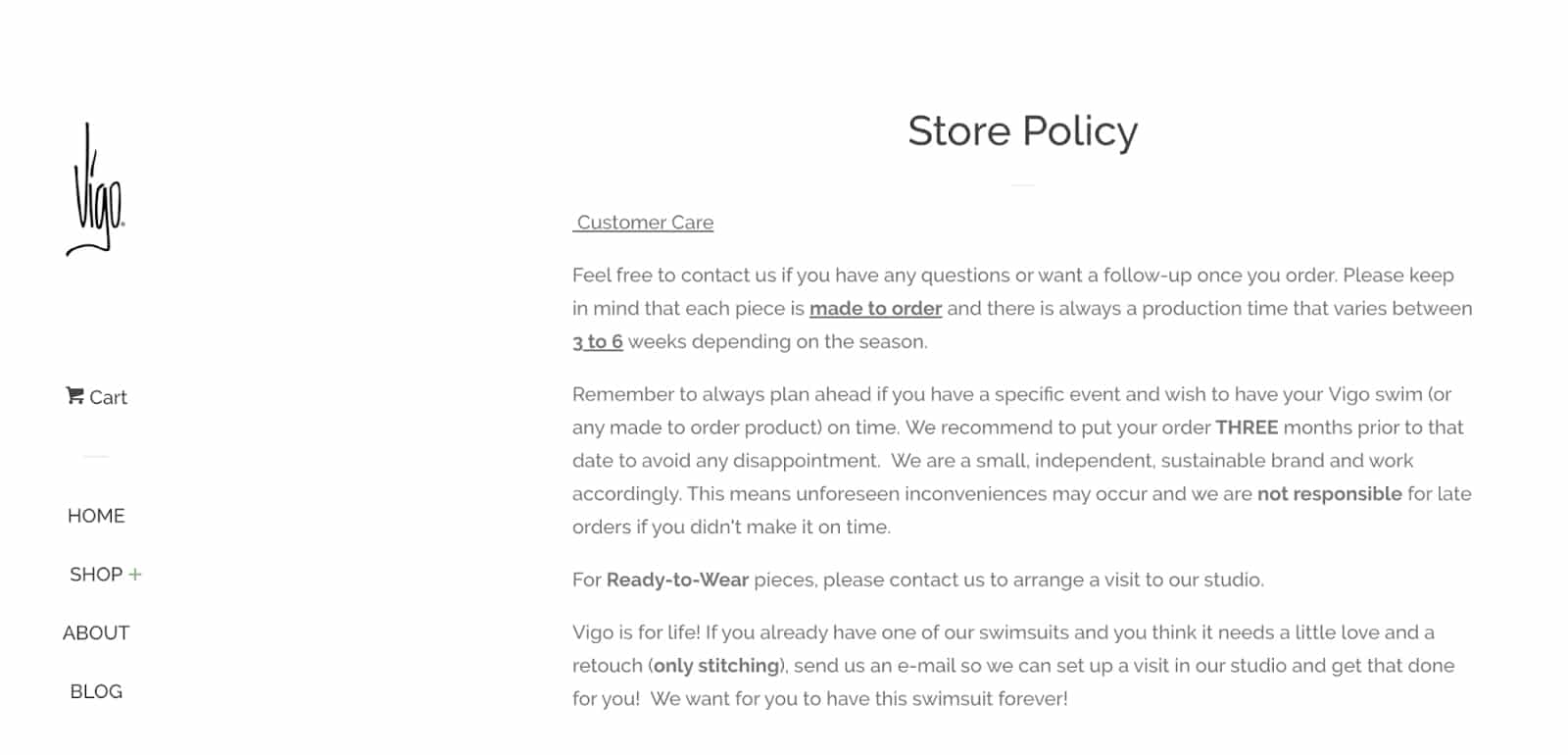

Vigo Swim

Puerto Rico-based sustainable swimwear brand Vigo Swim uses the JIT method. However, its operations are on a much smaller scale than Apple’s.

Every swimsuit is handmade, many of which are made to order (though the online retailer does offer a selection of ready-to-buy pieces). In this case, Vigo Swim is the manufacturer, so it has tighter control over operations.

The brand’s store policy that explains its production timeline. (Source: Vigo Swim)

Grayton Watches

Grayton Watches sells “urban-inspired watches.” To raise awareness, it launched a marketing campaign in which influencers could design and customize a watch. As such, the brand needed a lean production process that would put products in people’s hands with little lead time.

After implementing the JIT method, it was able to ship custom orders within 10 days of the purchase date—and it pumped capital into the business without making a major inventory investment.

A promotional post showing Grayton Watches’ product. (Source: Grayton Watches)

Kellogg’s

Household snack and cereal brand Kellogg’s also uses JIT inventory, with manufacturing plants located all over the world. The Kellogg Planning System (KPS) divided the supply chain into three distinct sectors and then optimized each. It involves weekly and monthly check-ins, which frequently lead to millions of dollars in savings due to production cycle optimizations.

Bottom Line

Starting a retail business involves a lot of decision-making and strategizing, and figuring out how to manage your inventory can be a make-or-break factor. The JIT inventory method is great for creating lean, agile operations that can respond to unexpected spikes and dips in demand, but it also has its challenges. It’s all a matter of analyzing your unique business needs to determine the best way to track your inventory.