Order fulfillment is the process of storing goods, packing orders, and shipping products to buyers. In a broad sense, order fulfillment is everything that happens after a customer places an order up to the moment they receive the order. Businesses can handle fulfillment in-house, outsource the function to fulfillment partners, dropship their orders, or combine methods.

Our top recommendation for small business order fulfillment is handing over the task to ShipBob. The company’s wide network of international warehouses allows for speedy two-day shipping to your customers. Plus, there are no minimum order volume requirements, and you only pay for the resources you use—making it a highly cost-effective way to manage fulfillment.

How Does Order Fulfillment Work?

Order fulfillment starts with receiving inbound wholesale shipments, sorting stock, and shelving inventory for efficient picking and packing.

Then, as orders come in, products are picked, inspected for quality and accuracy, packed, and labeled for shipment. Returns management (or reverse logistics) is often considered an extension of the fulfillment process.

If you’re doing in-house fulfillment, all of these steps will be completed in your facility—whether it’s a warehouse, storage unit, garage, or other space. If you outsource the fulfillment process (or use dropshipping), your fulfillment company will complete these steps.

We will explore those different fulfillment strategies below.

Order Fulfillment Strategies

There are four primary strategies for handling order fulfillment:

- In-house order fulfillment

- Third-party order fulfillment

- Dropshipping

- Hybrid fulfillment solution

In the News: Storefronts as Fulfillment Centers

Over the past several years, retailers like Walmart and Target have increasingly used their brick-and-mortar stores as fulfillment centers for online orders. If you’re operating brick-and-mortar stores in addition to an online store, the decision to outsource fulfillment isn’t as cut-and-dry.

Having an in-house fulfillment operation makes it easier to offer click-and-collect or buy online pickup in-store (BOPIS) shopping.

How to Choose an Order Fulfillment Strategy

- Measure Your Sales: Once you are consistently processing more than 10 daily orders, you are a candidate for outsourcing your fulfillment.

- Anticipate Future Growth: Once you hit the 10 orders per day threshold, consider your growth plans and whether your orders’ volume or complexity will change significantly in the near future. Outsourced fulfillment is much easier to scale quickly than expanding a personal warehouse or storage solution, software, and personnel.

- Identify and Locate Your Customers: Whether in-house or outsourced, ideally, your fulfillment center is located near your customers to minimize shipping time and fees.

Continue reading about the different fulfillment strategies:

- In-house vs Outsourced Fulfillment

- Dropshipping vs Fulfillment Companies

- How do Fulfillment Centers Work?

Why Is Order Fulfillment Important?

Beyond basic functionality, optimizing order fulfillment strategies is critical to ensure timely, cost-effective delivery. In fact, delivery windows influence 68% of purchase decisions, and many consumers want free shipping these days.

So, your order fulfillment strategies actually impact your bottom line—making it even more important to pay extra attention to your internal processes.

In short, order fulfillment is important because an effective fulfillment strategy will:

- Improve the customer experience through faster delivery times and choice of fulfillment options

- Lower operational and shipping costs

- Provide the infrastructure you need to grow

Order Fulfillment Best Practices

Whichever fulfillment strategy you choose, there are a few steps you can take to streamline your operations:

Being able to fulfill orders quickly and efficiently also requires having the right products in the right places at the right time.

Make sure you have a strong foundation for your inventory management process. You should have accurate product and vendor information, a system for tagging and labeling products, real-time stock updates, an established process for regular inventory counts, and a process for handling damaged or returned goods.

Once your foundation is in place, use your product data by analyzing retail inventory metrics like turnover ratios and carrying costs.

If you’re outsourcing your fulfillment, your fulfillment partner likely has warehouse optimization down to a science. However, if you’re using an in-house or hybrid approach, optimizing your warehouse layout can significantly speed up the picking and packing process and inventory counts.

In addition to product storage, you’ll need to dedicate space for picking and packing orders, receiving shipments, and outbound shipping.

Learn more in our warehouse layout guide.

Having the right product in the right places to fulfill orders quickly requires a lot of planning. You’ll need even more detailed planning if you have multiple fulfillment centers or locations.

Most sophisticated inventory management software, and even some retail point-of-sale (POS) systems like Shopify and Lightspeed, can help you automate demand forecasting so that you always have enough stock.

Whether you’re fulfilling orders in-house or through a fulfillment company, ensure all products are inspected as they are received and before they are shipped to customers. These checks should be systematized and documented for future reference.

In addition to inspecting individual products, your team or fulfillment partner should check orders against the packing slip or online order before being sealed up for shipping. Accidentally sending the wrong item is frustrating for customers. In addition to creating a poor customer experience, you’ll also spend time and money correcting the order and shipping out the right product.

Finally, standardize your packing procedures so that items are shipped safely and securely. Receiving a broken item is just as frustrating as receiving the wrong product. You can learn more in our guide to packing materials.

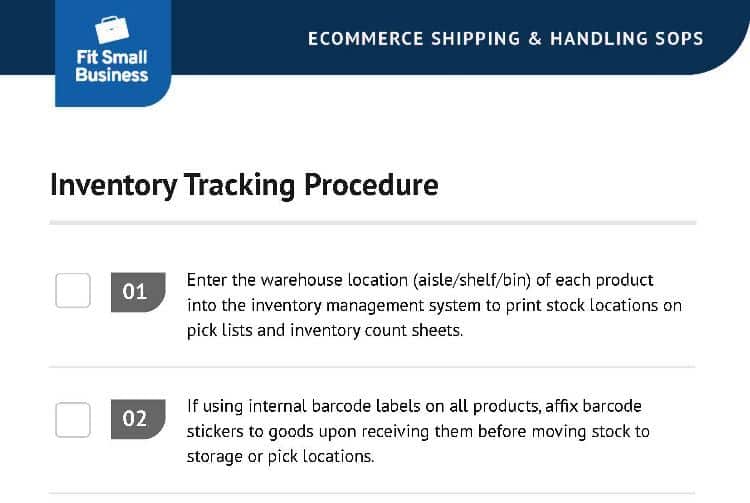

If you’re unsure where to start, use our ecommerce shipping and handling standard operating procedure (SOPs) as a starting point. You can tailor them to fit the needs of your operation.

Thank you for downloading!

Quick Tip:

If managing a facility and process takes you away from important business-building tasks, try using our recommended fulfillment company, ShipBob.

With ShipBob, it has low startup costs and gives you access to its web-based software that integrates with top sales channels for seamless order fulfillment.

Order Fulfillment Challenges for Small Businesses

Fulfillment has some challenges you’ll need to navigate year after year, alongside unique obstacles brought about by specific events or environments. Here are some important factors to remember as you manage your fulfillment process.

Order Fulfillment Frequently Asked Questions (FAQs)

Though order fulfillment is a simple logistical process, it can be time-consuming and labor-intensive. Plus, the infrastructure required to handle fulfillment efficiently (such as an industrial warehouse and ample staff) is too expensive for many small retailers.

New and growing companies often choose to outsource order fulfillment or use dropshipping. In contrast, more established businesses find that having operations in-house provides more control and can help them save on order fulfillment costs.

You can find an order fulfillment warehouse in this list of the best order fulfillment companies for small businesses.

Order fulfillment rate, or fill rate, is a metric that demonstrates a business’s ability to fulfill orders from available stock. To calculate fill rate, divide the number of orders processed by the total number of orders received. The higher the number, the better.

When an order is in fulfillment, it is either being processed, packed, or shipped.

Order fulfillment is the process of storing goods, packing orders, and shipping products to buyers. It encompasses everything that happens after a customer places an order up to when they receive it.

Bottom Line

Accurate and timely order fulfillment is the lifeblood of a successful ecommerce operation. To stay ahead of your competition, you must understand the entire order fulfillment process, embrace efficient habits, and manage costs end-to-end.

There are many ways to get orders into the hands of your customers, and often, a mix of fulfillment solutions is the best choice for a growing business. So, as you grow, look for flexible, as-needed fulfillment options that let you expand your capacity while controlling costs.